Introduction

In the world of Radio Frequency (RF) engineering and electronics procurement, terminology can often be the biggest barrier to selecting the right component. A frequent question we receive from our global clients—particularly those dealing with legacy equipment or Asian supply chains—is: “What is the difference between a BNC connector and a Q9 connector?”

At first glance, they look identical. They both utilize a bayonet locking mechanism, and they often fit into the same ports. However, treating them as interchangeable without understanding their technical nuances can lead to signal degradation, especially in high-frequency applications.

This guide clarifies the confusion. We will explore the historical origins of the “Q9” designation, compare the manufacturing standards (MIL-STD vs. Old GB), and explain why the modern BNC connector is the industry standard for reliable data, video, and power transmission.

Quick View The Differences:

| Feature | Standard BNC Connector | Q9 Connector (Legacy/Old Standard) |

| Origin | International (USA/IEC) | China (Old GB) |

| Frequency | DC – 4 GHz | DC – 500 MHz (Typical) |

| Impedance | Strict 50Ω / 75Ω | Nominal 50Ω (Inconsistent) |

| Insulator | PTFE (White) | Bakelite/ABS (Yellowish/Dark) |

| Contact Plating | Gold/Silver | Silver/Nickel |

| Performance | Low VSWR, High Fidelity | Higher Signal Loss |

Understanding the Basics: Definitions and Origins

To understand the difference, we must first look at the history of these two terms. The core distinction is not necessarily in the shape, but in the standardization system they belong to.

What is a BNC Connector?

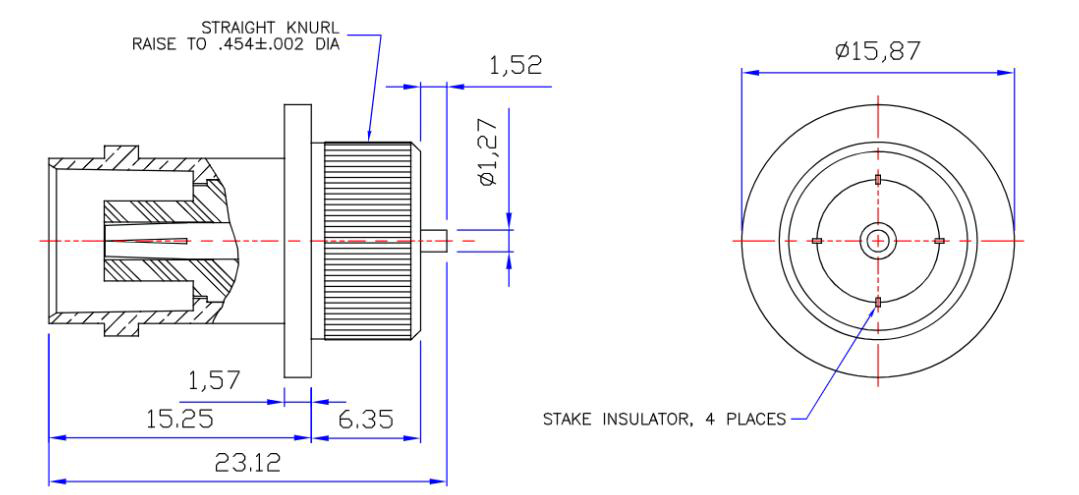

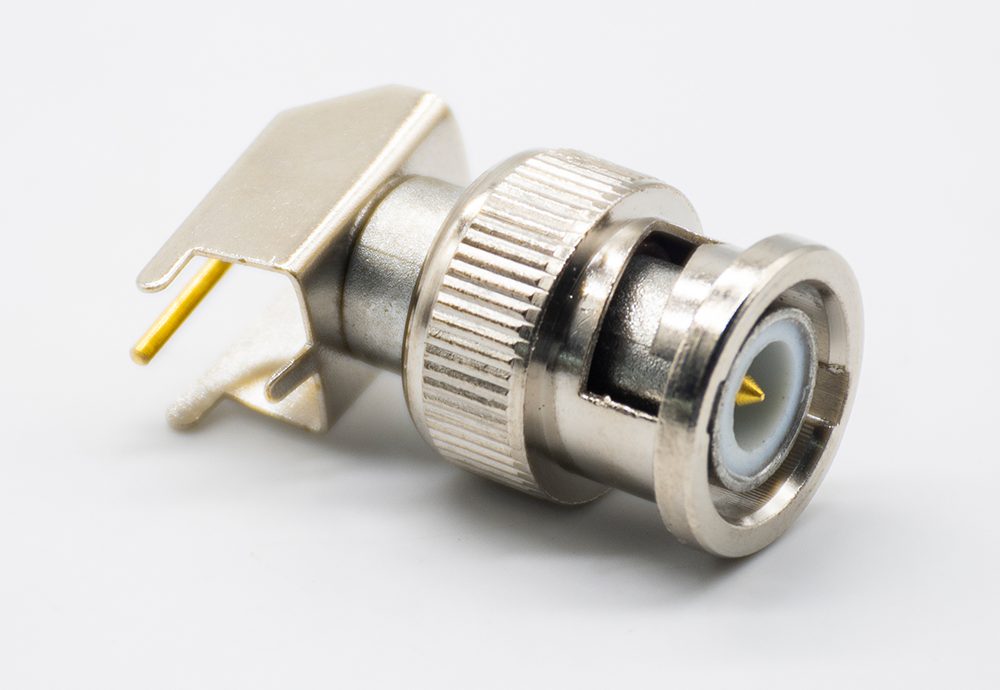

The BNC (Bayonet Neill–Concelman) connector is a miniature quick connect/disconnect radio frequency connector used for coaxial cable. It was named after its designers, Paul Neill of Bell Labs and Carl Concelman of Amphenol, and developed in the late 1940s.

BNC connectors are strictly governed by international standards, primarily MIL-STD-348 and IEC 60169-8 (International Electrotechnical Commission). These standards dictate precise dimensions, dielectric materials, and impedance levels (strictly 50Ω or 75Ω), ensuring that a BNC connector bought in Germany works perfectly with equipment made in the USA or Japan.

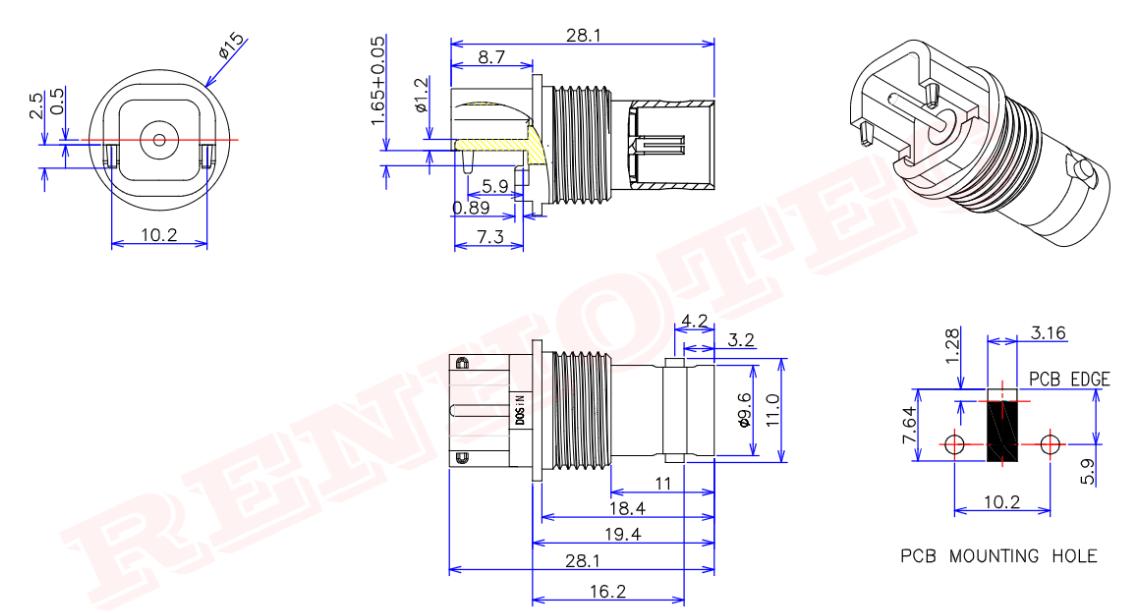

The BNC family includes several form factors designed to accommodate different installation needs:

| Type | Function/Usage | Application Context |

| BNC Male Connector | Attaches to the cable end, features a center pin and coupling nut. | Cable termination. |

| BNC Female Connector | Often mounted on panels or instruments. | Equipment interface, BNC bulkhead. |

| BNC T Connector (BNC Tee) | Splits the signal path into two, commonly used in bus network topologies. | Legacy network taps, test setups. |

| BNC Adapter | Converts BNC to other connector types (e.g., BNC to BNC, BNC to RJ45). | Interfacing different systems. |

What is a Q9 Connector?

The term “Q9” is a legacy designation primarily used in mainland China during the mid-to-late 20th century. It originates from China’s older National Standards (GB) or Ministry of Electronics Industry standards (SJ).

- “Q” stands for “Qia Kou” (卡口) or sometimes interpreted as the broad category of “Qiang” (Gun/Bayonet type), referring to the locking mechanism.

- “9” represents the specific series number within that catalog.

Essentially, Q9 was the Chinese domestic version of the BNC. While it was designed to be compatible with BNC interfaces, the manufacturing tolerances, materials, and frequency responses of older Q9 connectors often lagged behind the evolving international MIL-STD specifications. Today, the term is mostly used by veteran engineers or found in maintenance manuals for older instruments.

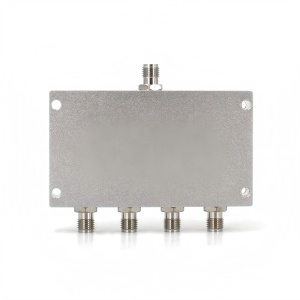

50Ω BNC:

75Ω BNC:

Detailed Comparison: BNC vs. Q9

While they share the same physical interface, the “invisible” differences determine their performance. Below is a detailed breakdown of where BNC and Q9 diverge.

Manufacturing Standards & Precision

Modern BNC connectors are manufactured with high-precision CNC machining to ensure a Voltage Standing Wave Ratio (VSWR) of less than 1.2 up to 4 GHz.

In contrast, vintage Q9 connectors were often produced using die-casting molds with looser tolerances. This can result in a loose mechanical fit or poor contact alignment, limiting their effective frequency range to below 500 MHz.

Materials and Impedance Control

- Insulation (Dielectric): Standard BNCs use PTFE (Teflon), which is white, heat-resistant, and maintains stable electrical properties. Old Q9 connectors often utilized Bakelite or inferior plastics, which appear yellowish/brown and have higher dielectric losses.

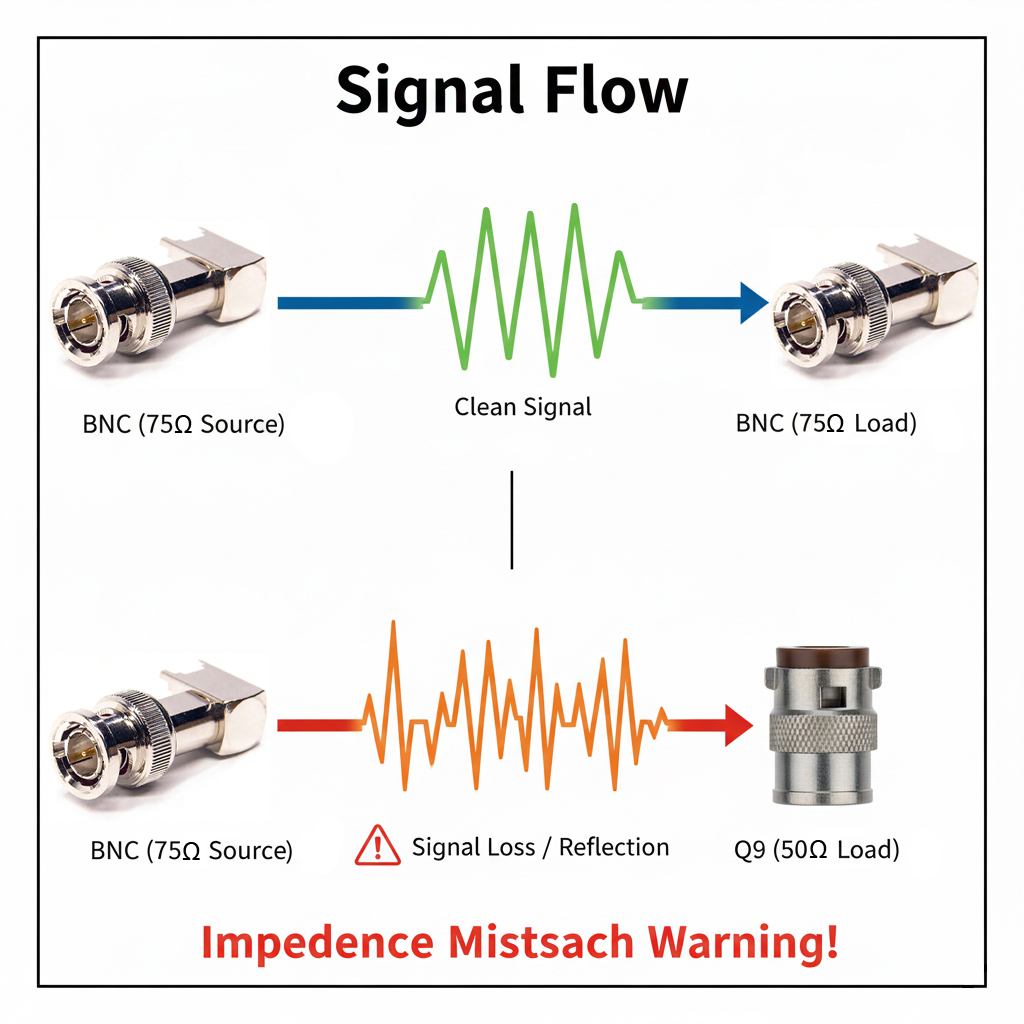

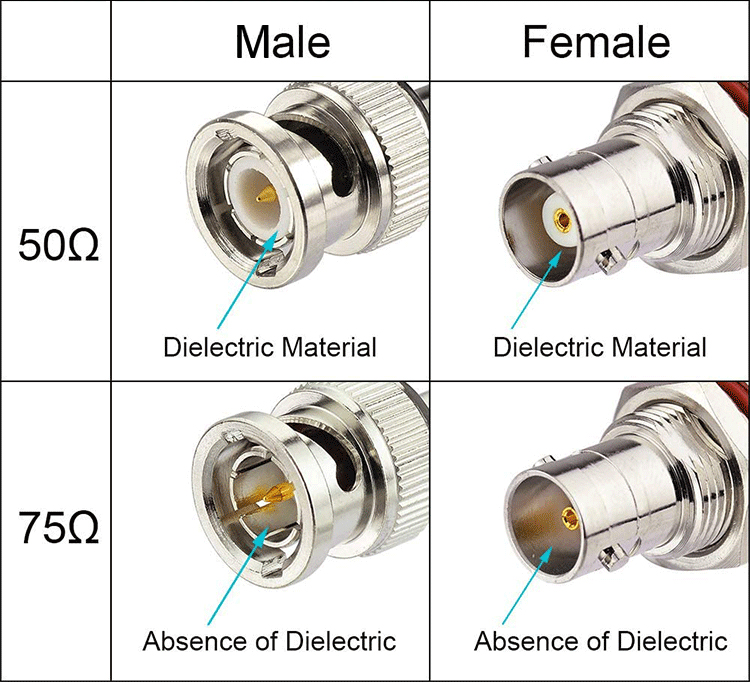

- Impedance (Ohm): BNC connectors have strictly defined 50 Ohm BNC Connector and 75 Ohm BNC Connector (physically distinguishable by the dielectric inside). Q9 connectors are nominally 50Ω, but in practice, their impedance consistency varies significantly, making them unsuitable for sensitive video transmission (which requires strict 75Ω).

Compatibility Guide: Can They Be Used Interchangeably?

This is the most critical question for our users. The answer involves two layers: Mechanical Compatibility and Electrical Compatibility.

- Mechanical Compatibility: YES

A Q9 plug will fit into a BNC jack, and vice versa. The bayonet lug dimensions and the inner diameter of the outer conductor are largely identical according to the basic design principles.

- Electrical Compatibility: CONDITIONAL

While they connect physically, mixing them comes with risks:

- Signal Reflection: Using a Q9 connector on a high-speed digital video line (SDI) designed for 75Ω BNC will cause impedance mismatch. This leads to signal reflection, ghosting in video, or data packet loss.

- Contact Oxidation: Older Q9 connectors often use silver plating that may have oxidized over decades (turning black). Plugging a tarnished Q9 into a new gold-plated BNC jack can contaminate the contact surface and increase resistance.

Application Scenarios: Where Will You Find Them?

Understanding where these connectors are typically found helps in making the right replacement choice.

- Scenario A: The Q9 Domain (Legacy)

You will mostly encounter strict “Q9” connectors in vintage equipment manufactured before the 1990s, such as:- Old analog oscilloscopes (Made in China).

- Function generators in university physics labs.

- Early industrial control systems using lower frequencies (<100MHz).

- Recommendation: If restoring a museum piece, a Q9 is authentic. For functionality, upgrade to BNC.

- Scenario B: The BNC Domain (Modern Standard)

BNC is the omnipresent standard for:- HD-SDI / 4K Video: Requires strictly matched 75Ω BNCs.

- Network & Telecom: DS3 Telco central office interconnects.

- Aerospace & Defense: Mil-spec versions for rugged environments.

- BNC to RJ45 adapter for integrating older BNC-based networks into modern twisted-pair systems, and various patch cables (BNC to BNC) for laboratory use.

- Recommendation: Always use new, certified BNC connectors.

Why You Should Choose Standard BNC Connectors?

If you are looking to purchase connectors for a new project or to repair old equipment, the choice is clear: Buy Standard BNC.

Even if your old schematic says “Q9”, a modern BNC connector from a reputable manufacturer like Renhotec serves as a superior upgrade. It offers:

-

Better Materials: Gold-plated center pins for corrosion resistance.

-

Frequency Stability: Reliable performance up to 4GHz.

-

Global Compatibility: Fits any standard port worldwide.

We provide a wide range of BNC connectors compatible with various cable types (RG58, RG59, RG174, etc.) and mounting styles (PCB Mount, Bulkhead).

Typical Applications and BNC Connector Selection Guide

BNC connectors are ubiquitous due to their reliability and ease of use, but choosing the right one hinges entirely on impedance matching.

| Step | Question | Recommended Choice |

| 1. Application | Is it Video/Broadcast or Data/RF/Test? | Video → 75Ω; Data/RF → 50Ω |

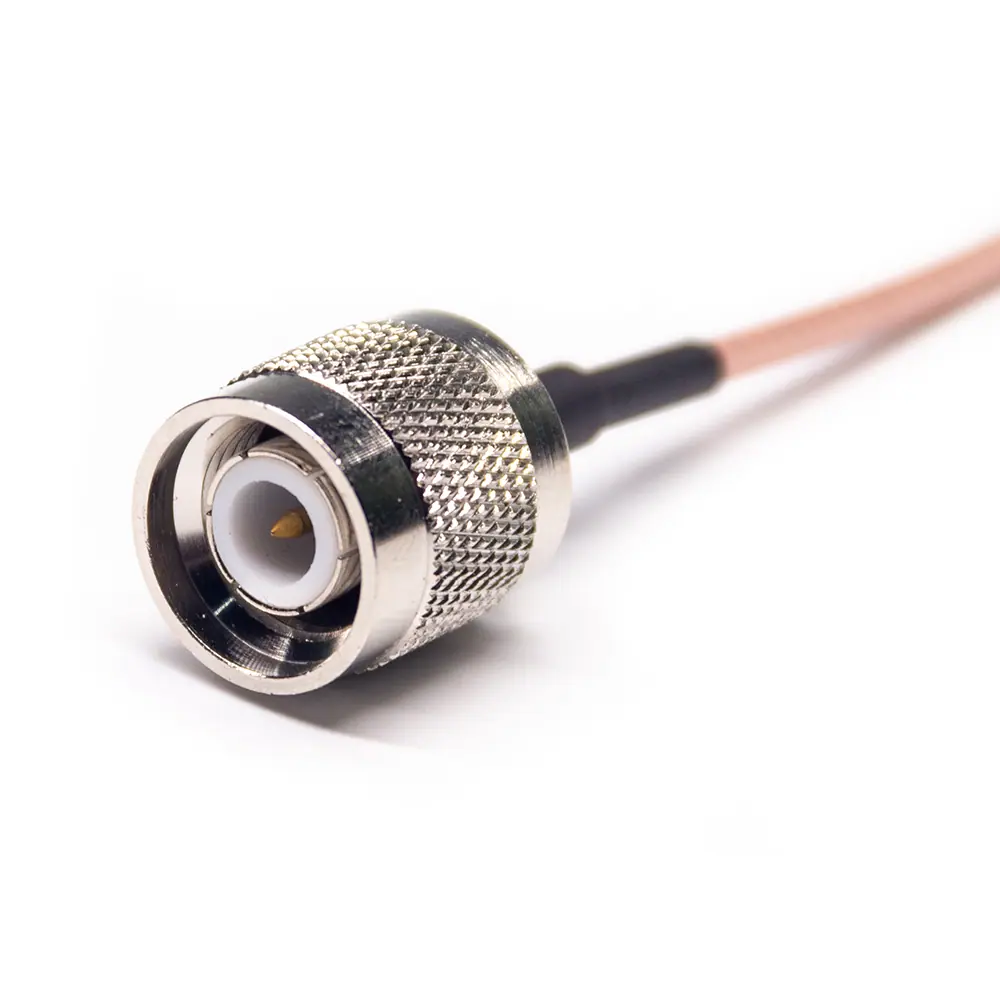

| 2. Frequency | Is the signal > 4 GHz? | BNC performance degrades; consider TNC (threaded BNC) or N-Type. |

| 3. Interface | Do you need quick connect/disconnect or secure lock? | Quick Connect → BNC; Secure Lock → TNC/SMA. |

FAQ

Q1: Is Q9 exactly the same as BNC?

A: Not exactly. Q9 is the older Chinese standard name for the BNC interface. While they mate physically, modern BNC connectors follow stricter international standards (IEC/MIL) and offer better electrical performance than old Q9 parts.

Q2: Can I use a BNC connector on a device labeled “Q9 Output”?

A: Yes, absolutely. A standard BNC connector is perfectly compatible with a Q9 port and will likely provide a better, more stable connection than the original plug.

Q3: How do I tell if my connector is 50 Ohm or 75 Ohm?

A: Look at the internal dielectric (the white plastic inside). If the dielectric extends to the outer rim, it is usually 50Ω. If there is air surrounding the dielectric (making the center pin look more exposed), it is 75Ω. (Note: Old Q9 connectors may not follow this visual rule strictly).

Q4: Where can I buy Q9 connectors today?

A: It is difficult to find new connectors sold strictly as “Q9” except from surplus stock. You should purchase BNC connectors, which are the direct, modern equivalent.

Q5: What Should I Look for in a Reliable BNC Connector Manufacturer?

A: Look for a BNC connector manufacturer that emphasizes three key areas: low Return Loss (VSWR) for optimal signal integrity, high-quality plating (e.g., Nickel or Gold) for durability and corrosion resistance, and proven ability to meet industry specifications (e.g., MIL-PRF-39012) for custom or high-volume orders.

Contact Us

Still unsure if you need a 50Ω or 75Ω connector for your application? Or are you looking to replace outdated Q9 components in bulk?

Contact our engineering team [email protected]. We can help you cross-reference your old part numbers and supply high-performance BNC solutions and BNC cables assemblies tailored to your industry.