FAKRA and HSD connectors, as two major high-performance connector series, have become the mainstream standard for connecting various electronic systems in intelligent connected vehicles. With the further improvement of automotive electronics and intelligence, they will continue to evolve in smaller, more modular and intelligent directions, providing powerful technical support for enhancing vehicle performance and decreasing costs.

I. Introduction of FAKRA and HSD Connector

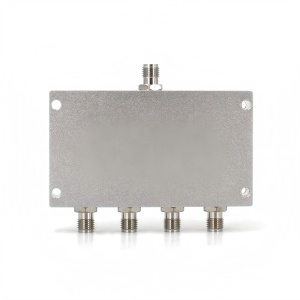

FAKRA has 5 types and over 500 models with compact structures, supporting up to 20A current. It is predominantly used for medium and low-speed signal and power connections, such as infotainment and undercarriage systems.

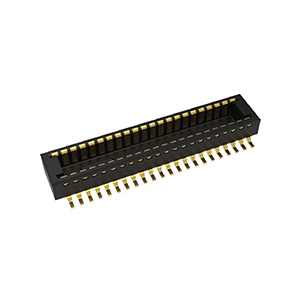

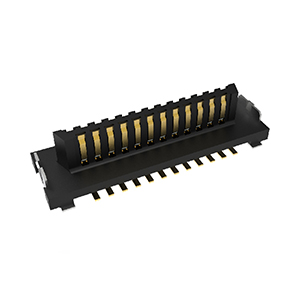

HSD has over 3,000 models and 8-34 SHELL sizes, primarily used for high-density complex signal connections, such as ADAS and connected systems. Both of them possess excellent fire resistance, corrosion resistance and reliability, and have become the mainstream of automotive electronic connections.

FAKRA is superior in vibration resistance and waterproofing, mainly applied in harsh environments such as engine compartments. HSD is superior in EMI shielding and high-speed signal integrity, mainly used in passenger entertainment and assisted driving systems. HSD has more and more standardized interfaces, and is more widely applied in vehicle electronic architecture. FAKRA is better compact and used in space-constrained applications.

With the expanding level of automotive electronics, these two major connector series will remain to mature in smaller, lighter and more intelligent directions to provide support for upgrading vehicle performance and cost optimization. They will form differentiated complementary applications to jointly foster innovation in automotive electronic technology.

II. Differences between FAKRA and HSD Connectors

Although FAKRA and HSD connectors have excellent fire resistance, corrosion resistance and reliability, there are some differences in their product characteristics and applicable scenarios.

FAKRA connectors have 5 types and over 500 models with compact structure, sustaining up to 20A current. They are primarily used for medium and low-speed signal and power connections, such as infotainment and undercarriage systems. FAKRA is superior in vibration resistance and waterproofing, principally used in harsh environments such as engine compartments.

HSD connectors have over 3,000 models and 8-34 SHELL sizes. They are mainly used for high-density complex signal connections, such as ADAS and connected systems. Compared with FAKRA, HSD is superior in EMI shielding and high-speed signal integrity. Therefore, HSD connectors are mainly used in passenger entertainment and assisted driving systems where require higher transmission performance. In addition, HSD has gradually standardized interfaces which make it be more widely utilized in vehicle electronic architecture. FAKRA is better compact and used in space-constrained applications.

In the future, with the rising level of automotive electronics, these two major connector series will form differentiated complementary applications to jointly promote innovation in automotive electronic technology. HSD will concentrate on high-speed data exchange, and FAKRA will focus on power supply and harsh environment applications. Together they will provide significant support for the performance improvement, intelligent transformation and cost optimization of vehicles.

III. Applications in In-Vehicle Infotainment Systems

Ultra-high 8K screens and multiple cameras require FAKRA D type 10GB/s rate to exchange high-definition data. Rearview video and car theater require HSD DASH 20/24/34, etc. to transmit high-definition video and audio.

The second and third row entertainment systems demand FAKRA E/HSD 24/34 SHELL to connect multiple displays and speakers to transmit stereo audio and visual content. These connectors support DP/HDMI and other high-speed MI to deliver an ultimate visual and audio experience.

The intelligent connected platform can access the data of each in-vehicle system through these connectors to deliver tailored content and services. This requires connectors to have the ability to transmit high-speed and stably. In the future, with the commercialization of autonomous driving, connectors will have higher requirements for transmitting ultra-large capacity content.

IV. Applications in Advanced Driver Assistance Systems (ADAS)

Traffic sign identification, emergency braking and other ADAS systems gather information through multiple cameras and radars, requiring HSD 20-24 SHELL 10GB/s rate and high anti-interference to transmit data to the central processor. This requires connectors to have zero packet loss and millisecond delay.

HSD HD is specifically intended for high-speed and stable data transmission and is applied in traffic sign recognition and pedestrian recognition systems. The S type is used in emergency braking systems, requiring high reliability and zero error. These connectors will remain to increase speed and enhance anti-interference to assist ADAS to switch to autonomous driving.

V2X technology also needs these connectors to achieve connectivity and communication between vehicles and road infrastructure and pedestrians, providing technical support for traffic control and safety monitoring. With the advancement of intelligent connected vehicles to autonomous driving, the important role of connectors will be further highlighted.

V. Applications in New Energy Vehicles

The electronic dashboard connecting multiple sensors requires HSD 8-16 SHELL. The battery control system(BMS) connecting temperature control and heat dissipation requires explosion-proof FAKRA A/B type. This requires connectors to maintain high stability when operating in high-temperature and high-voltage environments.

The motor control unit connecting the drive motor and the undercarriage components requires HSD 20-34 SHELL to transmit a substantial amount of control data and signals. The underlying connection requires high stability in extreme environments. These connectors are demanded to be compact, lightweight, and intelligent to promote better performance and lower cost of new energy vehicles.

Conclusion

FAKRA and HSD connectors have become essential and superior components in modern automotive electronics. They provide strong support for performance improvement, intelligent transformation and cost optimization of new vehicles. With the increasing electrification and intellectualization of automobiles, FAKRA and HSD connectors will be further developed in a more compact, modular and intelligent direction. They will continue to promote innovation in vehicle electronic technology and take automotive electronics to new heights.