Introduction: The Miniaturization Maze in RF Design

In the rapidly evolving landscapes of 5G infrastructure, aerospace defense, and portable medical devices, the demand for RF interconnects is driven by a single, unrelenting mantra: smaller, faster, and lighter. The classic SMA connector has been the industry workhorse since the 1960s, offering a reliable balance of performance and cost. However, as modern PCB layouts become increasingly dense and operating frequencies climb higher into the millimeter-wave spectrum, the standard SMA is facing physical and electrical limitations.

Engineers are frequently caught in a dilemma: Should you stick with the universally available SMA, or is it time to migrate to microminiature alternatives like SSMA or SSMB? Making the wrong choice is not just about physical fit; it can lead to signal degradation at high frequencies, impedance mismatches, or mechanical failure under vibration.

This comprehensive guide dissects the technical nuances—from thread mechanics to frequency cutoffs—of these three connector types. We will go beyond the datasheet to help you understand the “why” behind the specs, ensuring your signal chain remains uncompromised.

Precision Technology and High-Speed RF

To help you make a quick decision, here is a direct specification comparison.

Core Definitions: A Snapshot of SMA, SSMA, and SSMB

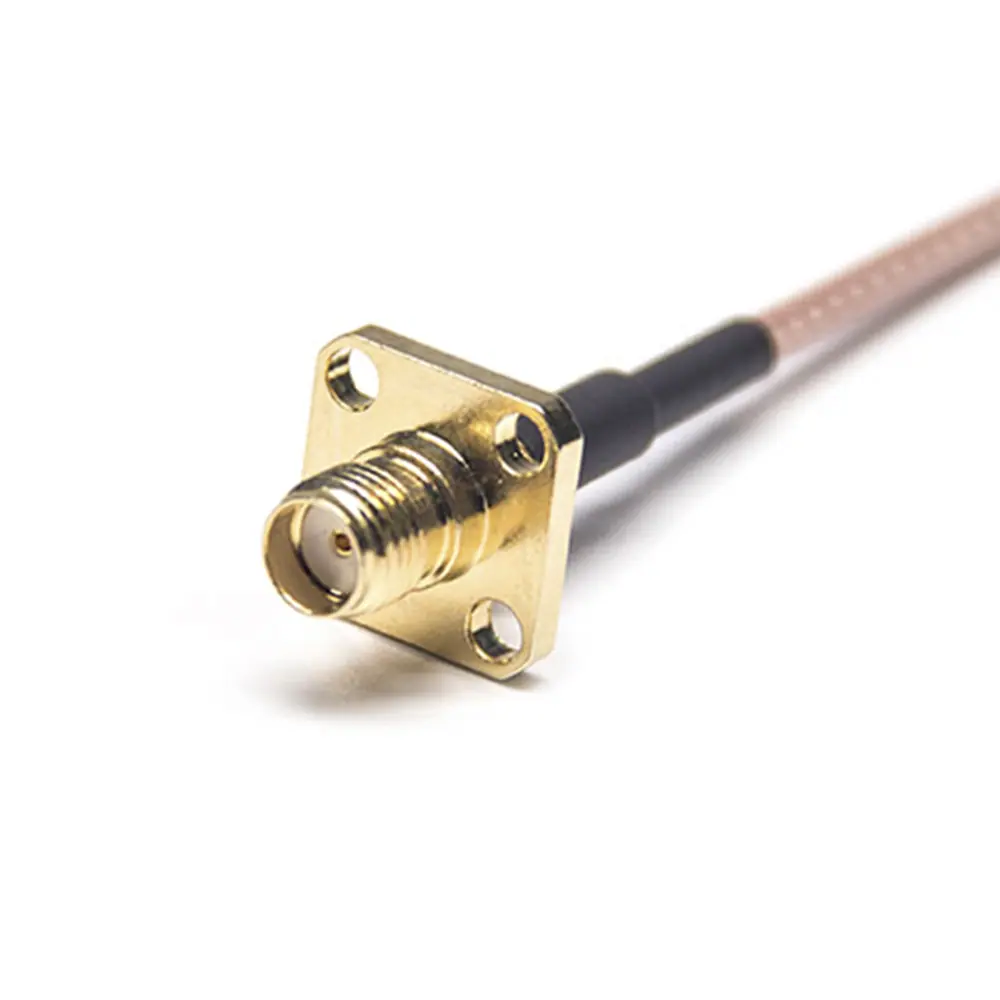

SMA

As noted in standard RF product guides, the SMA is a semi-precision coaxial RF connector. It features a threaded coupling mechanism and is the most widely used connector for microwave applications.

-

Interface: 1/4-36 UNS thread.

-

Key Feature: Excellent mechanical durability and electrical performance.

-

Standard Frequency: Typically rated DC to 18 GHz for standard variants.

SMA Male and Female RF Connectors

SSMA

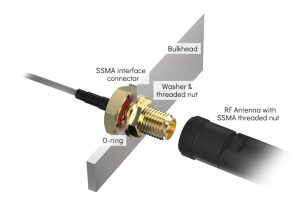

Think of the SSMA as the “cinematic sequel” to the SMA—designed to be sleeker and faster. It is essentially a scaled-down version, approximately 70% the size of an SMA.

-

Interface: Smaller 10-36 UNS thread.

-

Key Feature: Designed specifically for millimeter-wave applications where the SMA is too bulky or cannot support the frequency.

-

Standard Frequency: Extends up to 35 GHz or 40 GHz

SSMA Male and Female RF Connectors

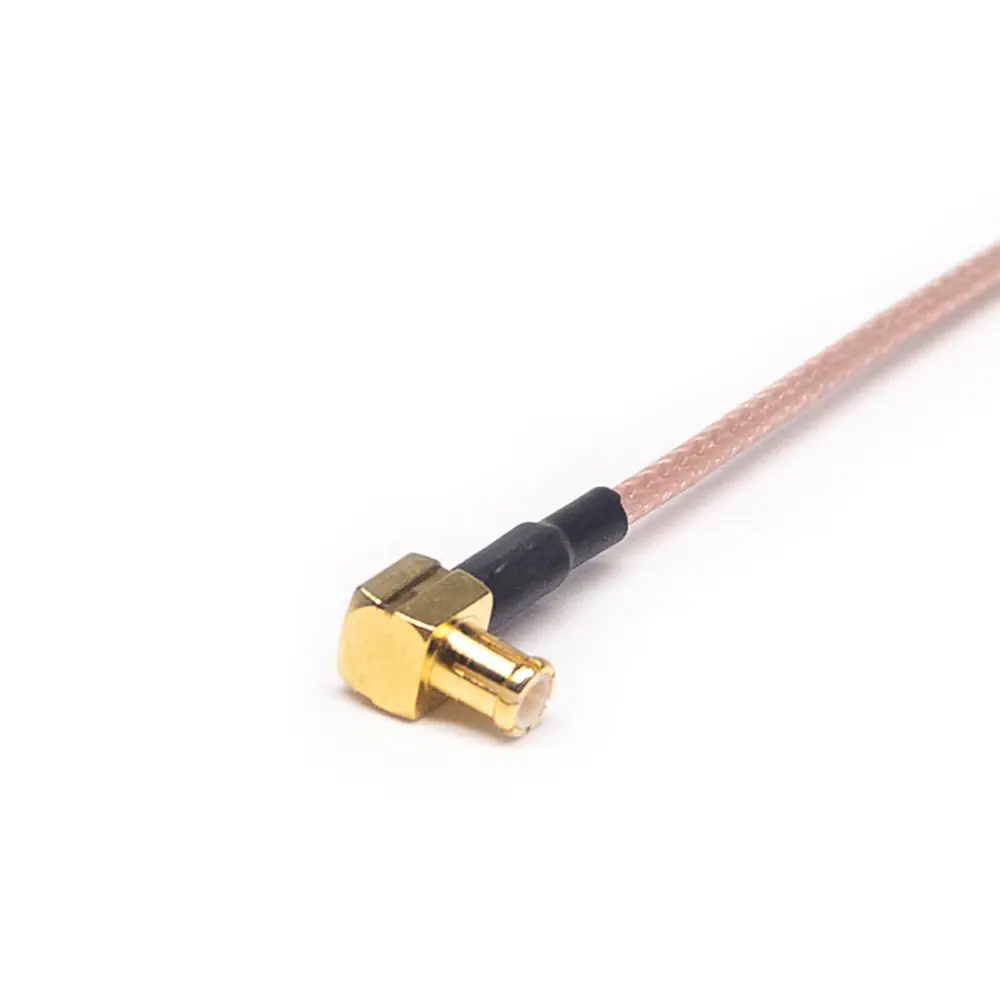

SSMB

The SSMB is the microminiature version of the standard SMB (SubMiniature version B). Unlike the threaded SMA family, it features a snap-on coupling mechanism.

-

Interface: Snap-on interface (no threads).

-

Key Feature: Allows for rapid connection and disconnection in tight spaces, ideal for internal cabling.

-

Standard Frequency: Generally operates DC to 12.4 GHz.

SSMB Male and Female RF Connectors

Deep Dive I: SMA vs. SSMA — Performance & Space

The battle between SMA and SSMA is usually fought in high-tech arenas like satellite communications and military guidance systems. The choice here is a direct trade-off between frequency handling and mechanical handling.

Size and Thread Mechanics

The most obvious difference is physical. While the SMA uses a robust 1/4-36 thread, the SSMA scales this down to a 10-36 thread. This reduction allows for significantly higher packaging density on PCBs. However, there is a usability caveat: the smaller threads of the SSMA are more delicate. They require precise torque application during assembly to avoid stripping. While an SMA is forgiving enough for field technicians to tighten by hand (though a torque wrench is recommended), an SSMA almost strictly requires calibrated tools to prevent damage.

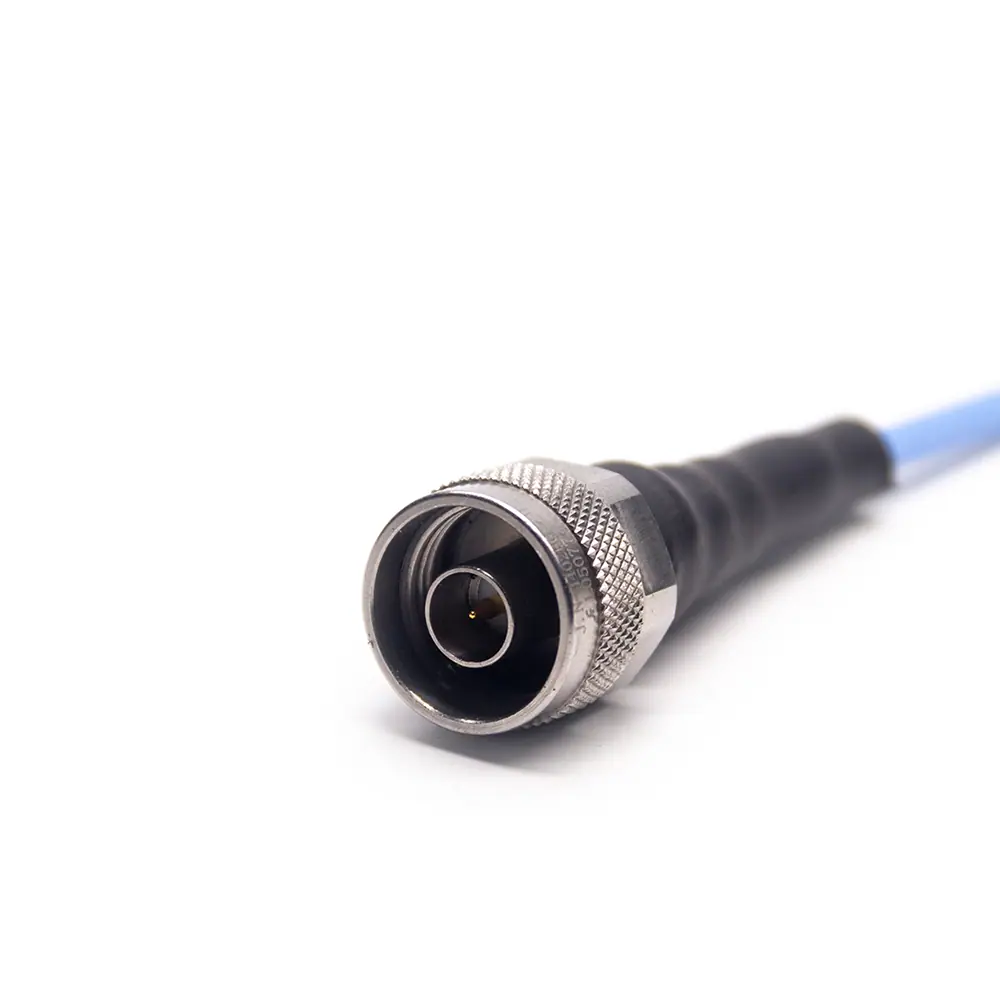

SSMA Bulkhead Interface for RF Antenna Connection

The Frequency Ceiling: Breaking the 18 GHz Barrier

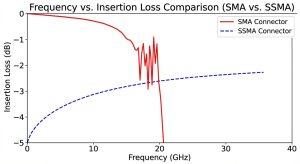

Frequency is the main technical differentiator. Standard SMAs are rated for DC to 18 GHz. Although “Precision SMA” variants exist that use air dielectrics to reach 26.5 GHz, the larger physical dimensions of the outer conductor inherently limit mode-free operation at millimeter-wave frequencies.

In contrast, the SSMA is purpose-built for high frequency. Its smaller outer conductor diameter pushes the cutoff mode frequency higher, making it a viable option for Ka-band (26.5–40 GHz) applications. If your system operates above 20 GHz, the SSMA (or 2.92mm) becomes necessary not just for size, but for physics.

Performance Comparison of SMA and SSMA RF Connectors

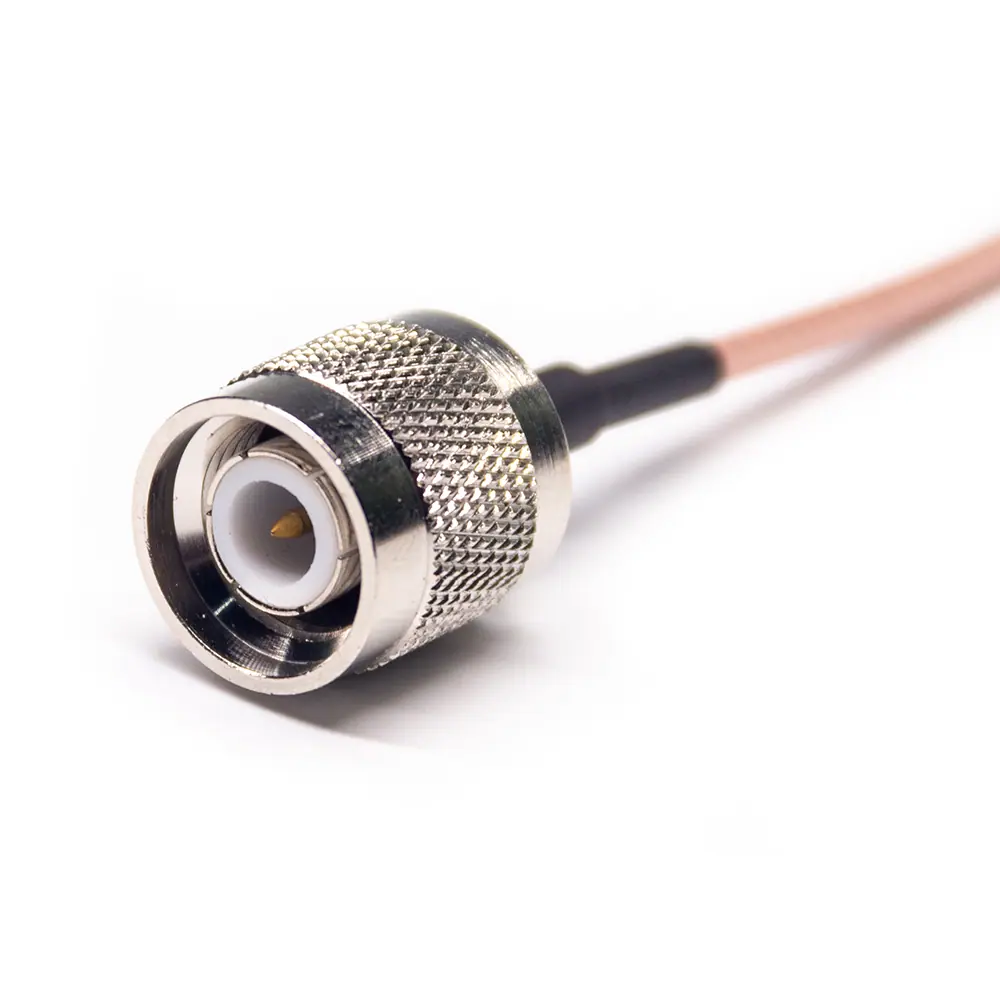

Deep Dive II: SMA vs. SSMB — Ruggedness vs. Convenience

Comparing SMA to SSMB is like comparing a heavy-duty bolt to a quick-release latch—they serve fundamentally different mechanical needs. This mirrors the classic “SMA vs SMB” debate but on a micro scale.

Coupling: Threaded vs. Snap-on

-

SMA (Threaded): As highlighted in comparisons of SMA connectors, the threaded coupling ensures a rock-solid connection that is impervious to heavy vibration. It is the gold standard for external antennas, avionics, or vehicle-mounted devices where the connection must never come loose.

-

SSMB (Snap-on): Inheriting the DNA of the SMB, the SSMB allows for quick mating. You simply push to connect and pull to disconnect. This is crucial for high-volume assembly lines where workers need to connect internal cables rapidly inside a consumer device enclosure.

SMA-Threaded and SSMB-Snap-on RF Connectors

The following is a horizontal comparison of the technical parameters of three different types of connectors.

Technical Comparison Matrix

Application Scenarios

-

Vibration Environments: If your device is a drone or a military vehicle exposed to shock, SMA (or SSMA) is the clear winner.

-

Confined Consumer Spaces: The SSMB is designed for the inside of equipment. Its spring-finger interface is convenient but has lower retention force. It is susceptible to momentary signal discontinuity (noise) under high vibration, making it less suitable for critical rugged applications.

Different Connectors for Application Scenarios

FAQ

Q1: Can I mate an SSMA connector directly with an SMA connector?

- No. Although they look similar, the thread sizes are different (1/4-36 for SMA vs 10-36 for SSMA). Forcing them together will damage the threads. You will need a precision adapter to connect them.

Q2: Is SSMB compatible with SMB?

- No. SSMB is a scaled-down version of SMB. They are not mechanically compatible and cannot be mated together without an adapter.

Q3: Why do some sources say SMA goes up to 26.5 GHz?

- Standard SMA is rated to 18 GHz. However, “Precision SMA” variants utilize higher quality stainless steel and optimized air dielectrics to extend performance to 26.5 GHz. For frequencies higher than that, SSMA or 2.92mm connectors are recommended to avoid mode issues.

Related Products

Contact Us

Find Your Precision RF Connection Solution

Selecting the right coaxial connector is crucial for optimal performance in high-frequency applications. Whether you need standard SMA connectors for reliable threaded connections in wireless communications, or customized solutions for aerospace and defense systems requiring stable performance up to 18 GHz, our engineering team has the expertise to support your requirements.

Contact our RF specialists at [email protected] to discuss your SMA connector needs, request custom designs, and access our complete RF Catalog!