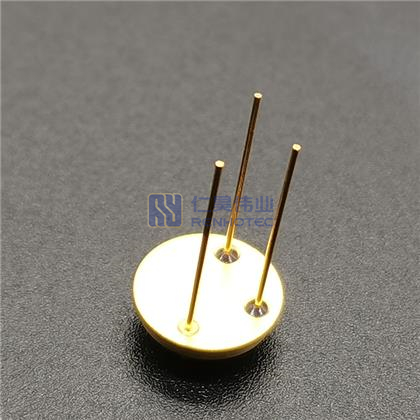

3 Pin Glass to Metal Seal Header – RHT-10418-03P

- Designed for high-pressure environments, providing robust protection and electrical isolation.

- Glass-to-metal hermetic seal ensures superior resistance against moisture, contaminants, and gases.

- Perfect for applications in aerospace, military, and industrial systems requiring reliable performance under pressure.

- Exceptional environmental protection, resistant to extreme temperatures, vibration, and shock.

- Ideal for applications that demand secure and consistent electrical connection under high-pressure conditions.

- Customizable to meet unique system requirements, including seal type, pin count, and configuration.

- Long-lasting, durable construction for mission-critical systems that require high reliability in demanding conditions.

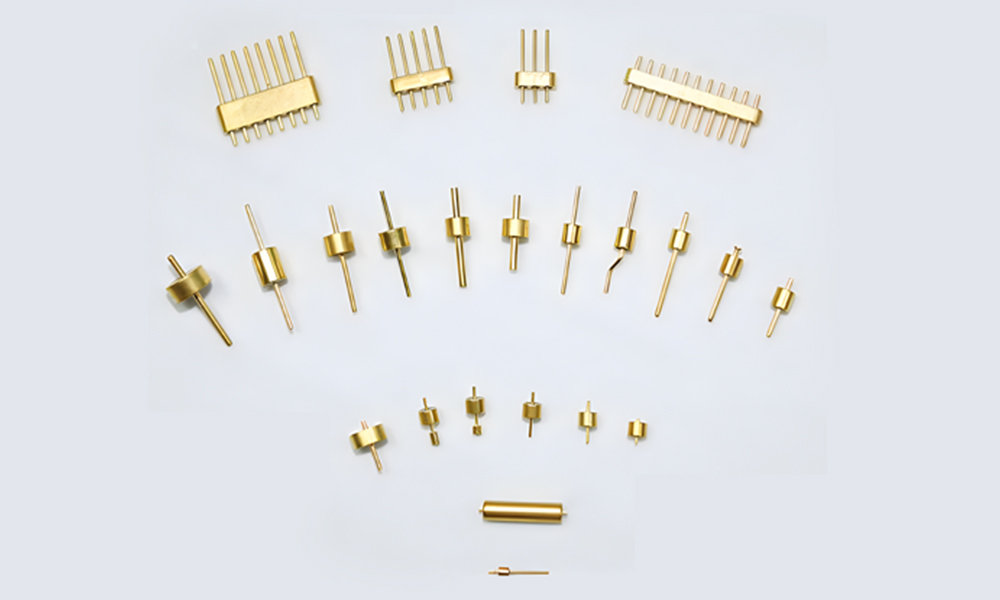

Glass to Metal Hermetic RF/DC Feedthroughs/Seals /Multi-pin Headers /Connector is also called Glass insulator. They are mainly used to transmit microwave signals, power signals and control signals between modules and modules, modules and components with gas sealing requirements. They are one of the most critical components in sealing components. The glass with low dielectric constant and low dielectric loss is used as insulating and supporting material. The housing and conductor is made of Kovar alloy that sintered under high temperature, and the surface is gold plated. The centerconductor has a variety of termination styles such as gold wire bonding, soldering and mating etc. Glass insulators are small, lightweight, hermetic, high reliable and have been widespread in electronics manufacturing industries in recent years.

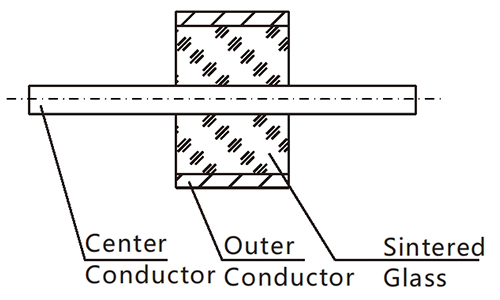

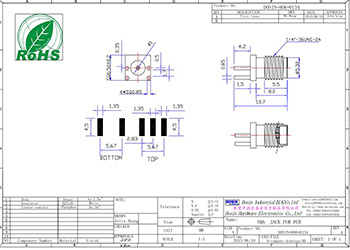

Structure

Glass insulator is composed of three parts: outer conductor/shell, glass medium and center conductor/pin.Its basic structure is shown in the figure.

Reliability Requirements

Hermeticity

≤1.01325×10-³Pa·cm³/s/s

Salt spray

Glass insulators shall be tested without severe corrosion and spotting.

Temperature shock

There shall be no cosmetic or mechanical damage after testing.

Applications

Our Advantages

Physical factory

Having a professional production team, selfproduced and self sold

Quality assurance

Through strict qualitycontrol, ensure quality

Customized

We can customize diff-erent specifications ac-cording to your needs

After sales system

Actively follow up andpromptly address anyissues

Production Process

1. Put forward demand

2. Sketch design

3. Production equipment

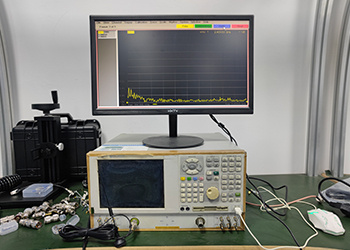

4. Production measurement

5. Product assembly

6. Quality test

7. Product packaging

8. Product packag box

9. Deliver goods

Product Specification

| Number of Positions | 3 Pin |

||

|---|---|---|---|

| Shell Material | 4J29 |

||

| Shell Finish | Nickel Plating, Ep.Ni≥3μm |

||

| Contact Finish | Nickel Plating, Ep.Ni≥3μm |

||

| Insulation Resistance | ≥800 MΩ (500V DC) |

||

| Number of Positions | 3 Pin |

Shell Material | 4J29 |

| Shell Finish | Nickel Plating, Ep.Ni≥3μm |

Contact Finish | Nickel Plating, Ep.Ni≥3μm |

| Insulation Resistance | ≥800 MΩ (500V DC) |

| Sealing | ≤2×10^-9 Pa·cm³/s |

||

|---|---|---|---|

| Production Technology | Glass Sintering |

||

| Customizable | Yes |

||

| Sealing | ≤2×10^-9 Pa·cm³/s |

Production Technology | Glass Sintering |

| Customizable | Yes |

| Number of Positions | 3 Pin |

|---|---|

| Shell Material | 4J29 |

| Shell Finish | Nickel Plating, Ep.Ni≥3μm |

| Contact Finish | Nickel Plating, Ep.Ni≥3μm |

| Sealing | ≤2×10^-9 Pa·cm³/s |

| Insulation Resistance | ≥800 MΩ (500V DC) |

| Production Technology | Glass Sintering |

| Customizable | Yes |