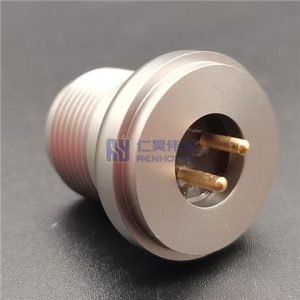

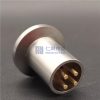

Glass-to-Metal Hermetic Seal Connector – RHT-10544-02P

- Glass-to-metal hermetic seal ensures high-level protection against moisture, gases, and contaminants, providing enhanced reliability in extreme environments.

- Designed for high-pressure, high-reliability applications in aerospace, military, and industrial sectors where failure is not an option.

- Customizable pin configurations to meet the specific needs of various mission-critical systems.

- Ideal for use in applications requiring robust electrical performance and resistance to vibration, shock, and temperature extremes.

- Low signal loss and excellent insulation resistance for reliable, long-term functionality in high-performance electronic systems.

- Highly durable, capable of withstanding extreme conditions such as high-pressure environments and harsh industrial applications.

- Ensures secure and stable connections, essential for systems demanding uncompromising performance and operational integrity.

Product Details

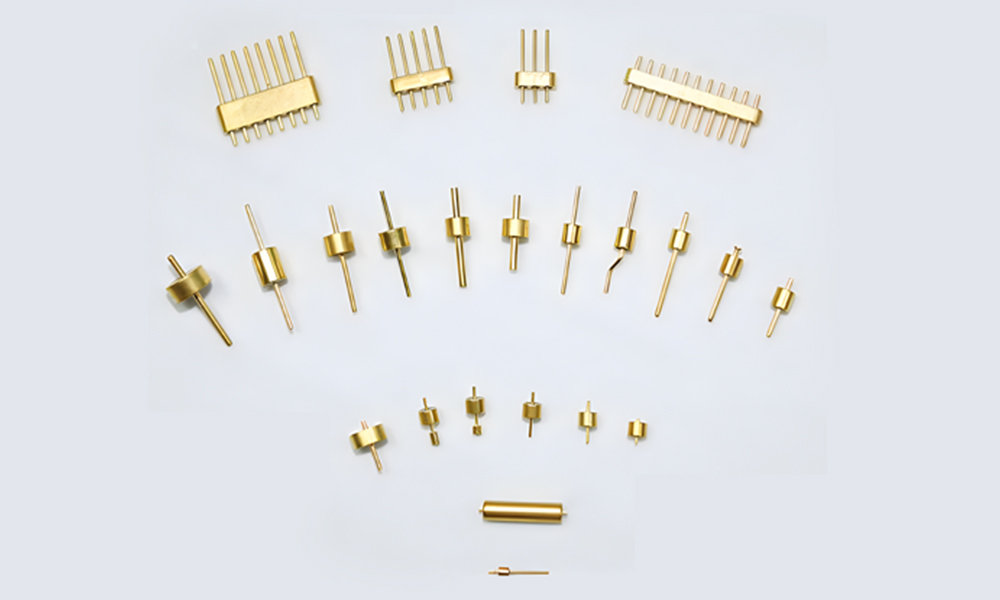

Glass to Metal Hermetic RF/DC Feedthroughs/Seals /Multi-pin Headers /Connector is also called Glass insulator. They are mainly used to transmit microwave signals, power signals and control signals between modules and modules, modules and components with gas sealing requirements. They are one of the most critical components in sealing components. The glass with low dielectric constant and low dielectric loss is used as insulating and supporting material. The housing and conductor is made of Kovar alloy that sintered under high temperature, and the surface is gold plated. The centerconductor has a variety of termination styles such as gold wire bonding, soldering and mating etc. Glass insulators are small, lightweight, hermetic, high reliable and have been widespread in electronics manufacturing industries in recent years.

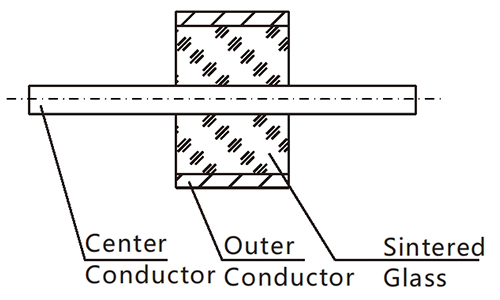

Structure

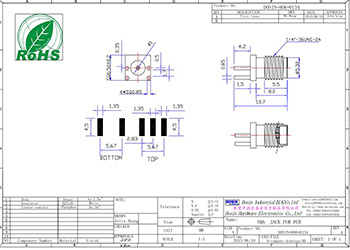

Glass insulator is composed of three parts: outer conductor/shell, glass medium and center conductor/pin.Its basic structure is shown in the figure.

Reliability Requirements

Hermeticity

≤1.01325×10-³Pa·cm³/s/s

Salt spray

Glass insulators shall be tested without severe corrosion and spotting.

Temperature shock

There shall be no cosmetic or mechanical damage after testing.

Applications

High Temperature Sensors

Implanted Medical Devices

Batteries and Capacitors

Automotive Airbag

Our Advantages

Production Process

1. Put forward demand

2. Sketch design

3. Production equipment

4. Production measurement

5. Product assembly

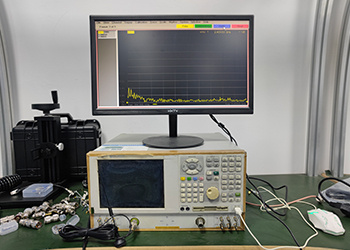

6. Quality test

7. Product packaging

8. Product packag box

9. Deliver goods

Product Specification

| Number of Positions | 2 Pin |

||

|---|---|---|---|

| Shell Material | Stainless Steel 316L |

||

| Shell Finish | Polishing, Passivation |

||

| Contact Finish | Gold Plated, Ep.Ni2.5Au0.5 |

||

| Insulation Resistance | ≥5000 MΩ (500V DC) |

||

| Number of Positions | 2 Pin |

Shell Material | Stainless Steel 316L |

| Shell Finish | Polishing, Passivation |

Contact Finish | Gold Plated, Ep.Ni2.5Au0.5 |

| Insulation Resistance | ≥5000 MΩ (500V DC) |

| Sealing | ≤1×10^-8 Pa·m³/s, ≤1×10^-9 Pa·m³/s |

||

|---|---|---|---|

| Production Technology | Glass Sintering |

||

| Customizable | Yes |

||

| Sealing | ≤1×10^-8 Pa·m³/s, ≤1×10^-9 Pa·m³/s |

Production Technology | Glass Sintering |

| Customizable | Yes |

| Number of Positions | 2 Pin |

|---|---|

| Shell Material | Stainless Steel 316L |

| Shell Finish | Polishing, Passivation |

| Contact Finish | Gold Plated, Ep.Ni2.5Au0.5 |

| Sealing | ≤1×10^-8 Pa·m³/s, ≤1×10^-9 Pa·m³/s |

| Insulation Resistance | ≥5000 MΩ (500V DC) |

| Production Technology | Glass Sintering |

| Customizable | Yes |