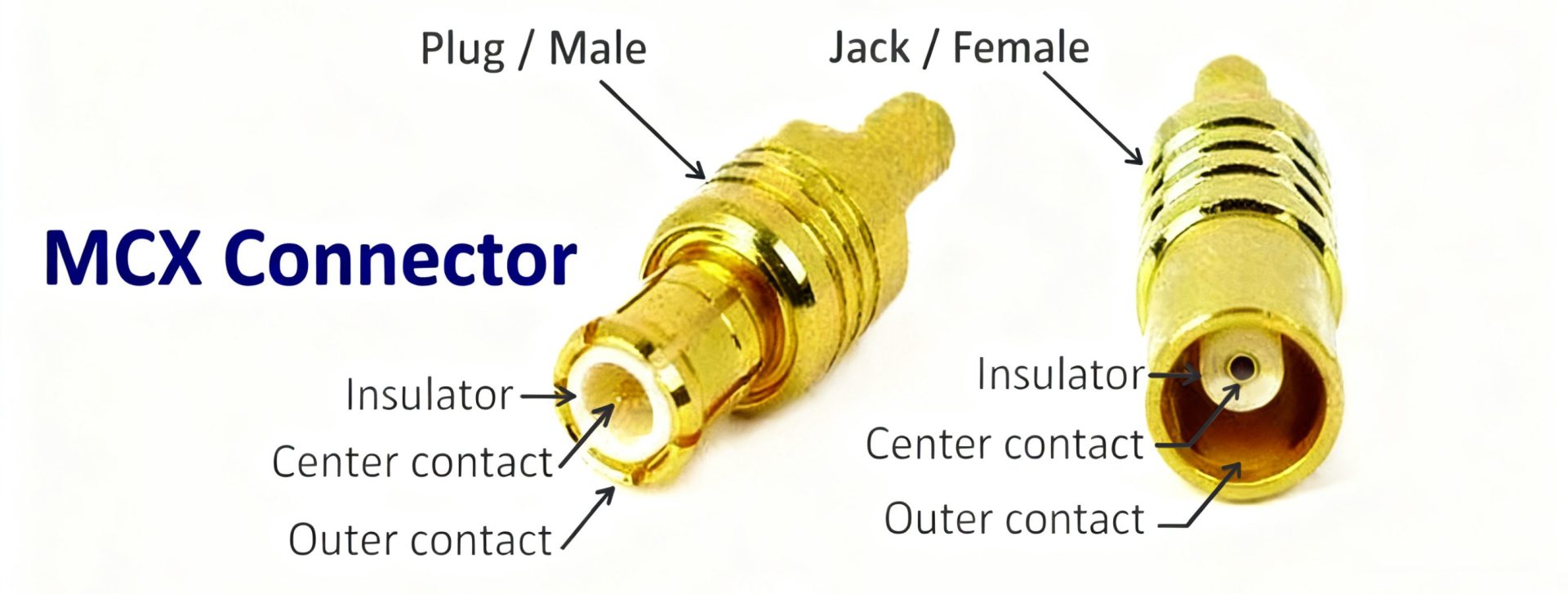

1. What is an MCX Female Connector? A Vital Component in RF Systems

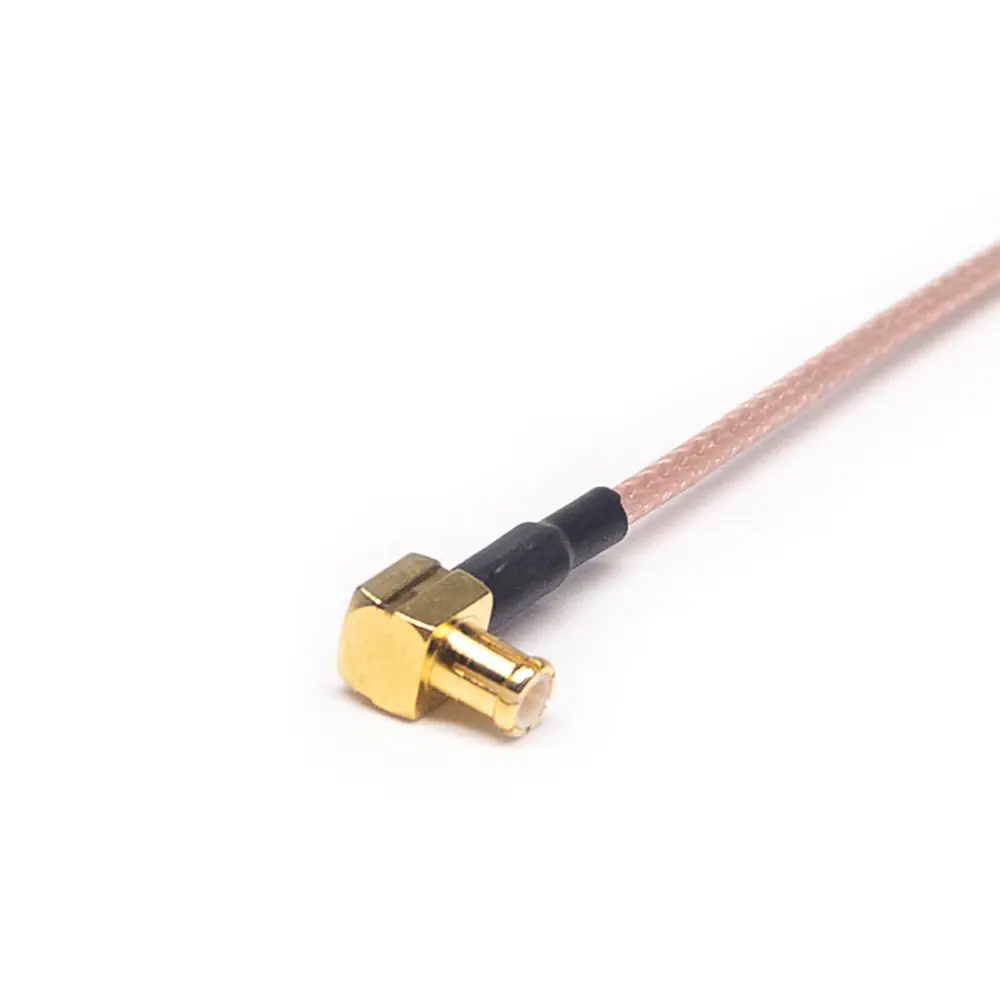

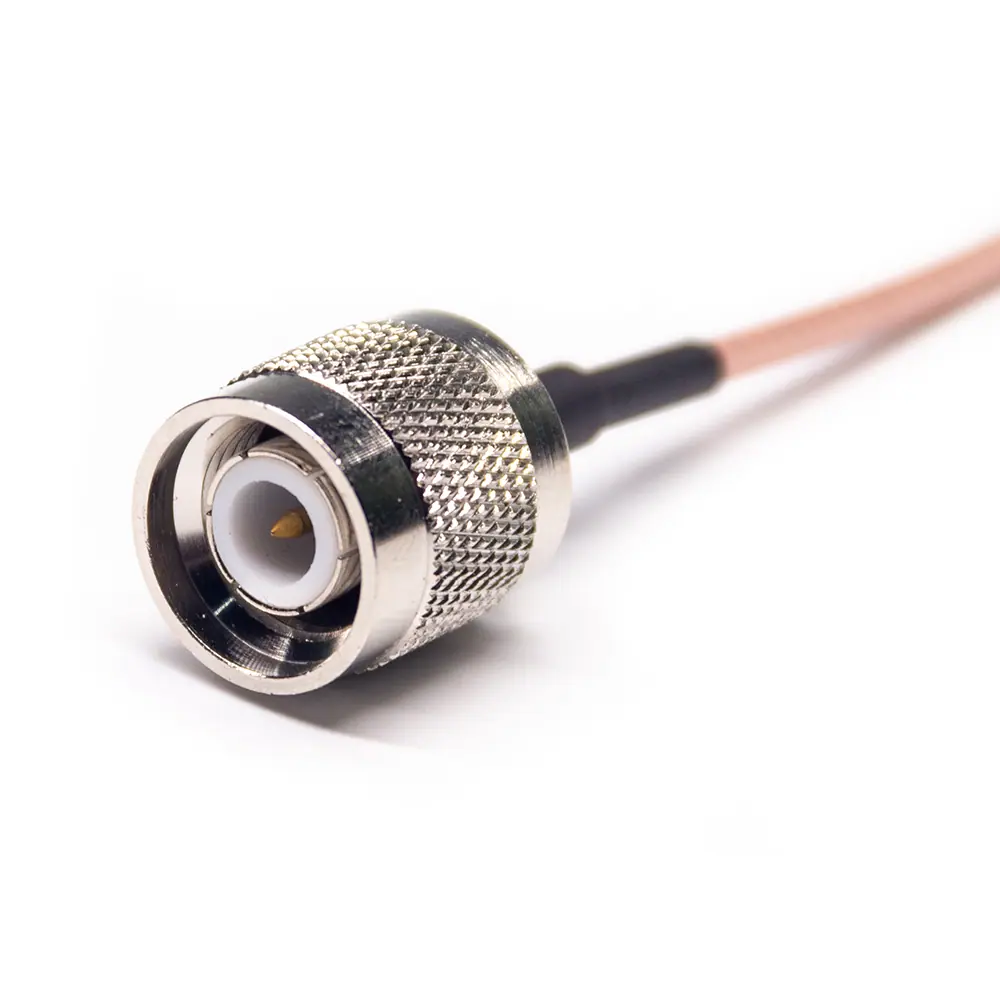

The Micro Coaxial (MCX) connector series is a staple in modern, compact Radio Frequency (RF) systems. It stands out due to its small form factor and secure snap-on coupling mechanism. Specifically, the MCX female connector—often referred to as the jack—plays the crucial role of the receiving port, typically mounted on a Printed Circuit Board (PCB) or a chassis bulkhead, designed to receive the male plug.

Its design adheres to the European CECC 22220 standard, making it internationally recognized for applications where size and weight must be minimized without sacrificing reliable performance up to 6 GHz. The key benefit is the push-pull snap coupling, which offers a quick-connect and quick-disconnect functionality, ideal for production environments and test equipment.

1.1 Core Technical Parameters and Performance Metrics

When selecting a reliable MCX female connector, engineers must scrutinize several key performance indicators (KPIs) to ensure system integrity:

- Impedance: Standard MCX connectors are 50Ω, widely used in wireless and data communication. While 75Ω versions exist, they are less common and typically reserved for specialized video applications.

- Frequency Range: Most commercial-grade MCX female parts are rated for reliable operation up to 6 GHz. High-performance versions may exceed this.

- Voltage Standing Wave Ratio (VSWR): A measure of impedance mismatch. A good connector will have a VSWR close to 1.0:1. A VSWR of ≤ 1.3:1 up to 6 GHz is generally considered excellent for this class.

- Insertion Loss: The signal power lost when the connector is introduced into the transmission line. Measured in decibels (dB), lower is always better.

- Mechanical Durability: Specifies the number of mating cycles the MCX female connector can withstand before performance degradation, typically around 500 cycles.

1.2 Why MCX Female Connectors Are the Preferred Choice for Compact RF Design

The primary differentiator for MCX lies in its size, offering approximately 30% less board area requirement compared to the larger SubMiniature B (SMB) connectors.

| Feature | MCX | SMB | MMCX |

| Coupling | Snap-on | Snap-on | Snap-on |

| Size/Footprint | Small | Medium | Very Small (Micro-miniature) |

| Max Frequency (Typical) | 6 GHz | 10 GHz | 6 GHz |

| Ease of Use | Excellent (Quick connect/disconnect) | Good | Fair (Requires tooling, tricky to connect manually) |

The ease of connecting and disconnecting the MCX makes it superior to its micro-miniature cousin, the MMCX, particularly in field-serviceable applications or during mass production testing. This makes the MCX female connector an optimal solution for GPS receivers, external antennas for WiFi/Bluetooth modules, test equipment, and compact telecommunication devices.

2. MCX Female Connector Selection Guide: From Materials to Interface Types

The longevity and performance of your RF system hinge on making the right component choices. The MCX female buying guide focuses on three critical factors: the mounting style, the materials used, and the corresponding performance characteristics.

2.1 Plating, Body Material, and Environmental Reliability

The material composition directly dictates the electrical performance, corrosion resistance, and cost of the MCX female connector.

- Body Material: High-quality connectors typically use Brass or Beryllium Copper (BeCu). Brass is cost-effective and easy to machine, while BeCu offers superior spring properties and mechanical endurance, especially for the center contact.

- Plating: Gold plating over a nickel underlayer is the industry standard. The gold (often 3μin to 50μin thick) is critical for minimizing insertion loss and ensuring excellent conductivity, preventing oxidation which is detrimental to high-frequency signals. The nickel underlayer enhances wear resistance and prevents migration of base metal.

- Environmental Sealing: For outdoor or harsh industrial environments, specify MCX female connectors with O-rings or sealed flanges to achieve ingress protection (IP) ratings (e.g., IP67).

2.2 Selecting the Right MCX Female Interface

The connection point of the MCX female connector to the main system is critical.

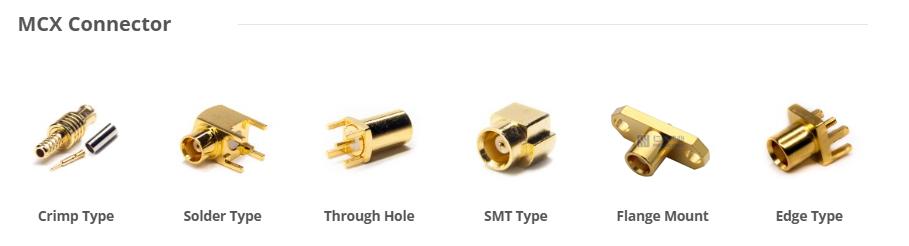

1. MCX Female PCB Mount:

- Focus: Directly soldered onto a printed circuit board.

- Variants: Surface Mount Technology (SMT) for automation, or Through-Hole (TH) for mechanical strength. The MCX female PCB mount type is chosen for permanent internal connections.

2. MCX Female Cable Mount:

- Focus: Terminated onto a flexible coaxial cable (e.g., RG-178, RG-316).

- Use Case: Ideal for connecting external antennas or linking between two sub-assemblies. Requires precise crimping or soldering.

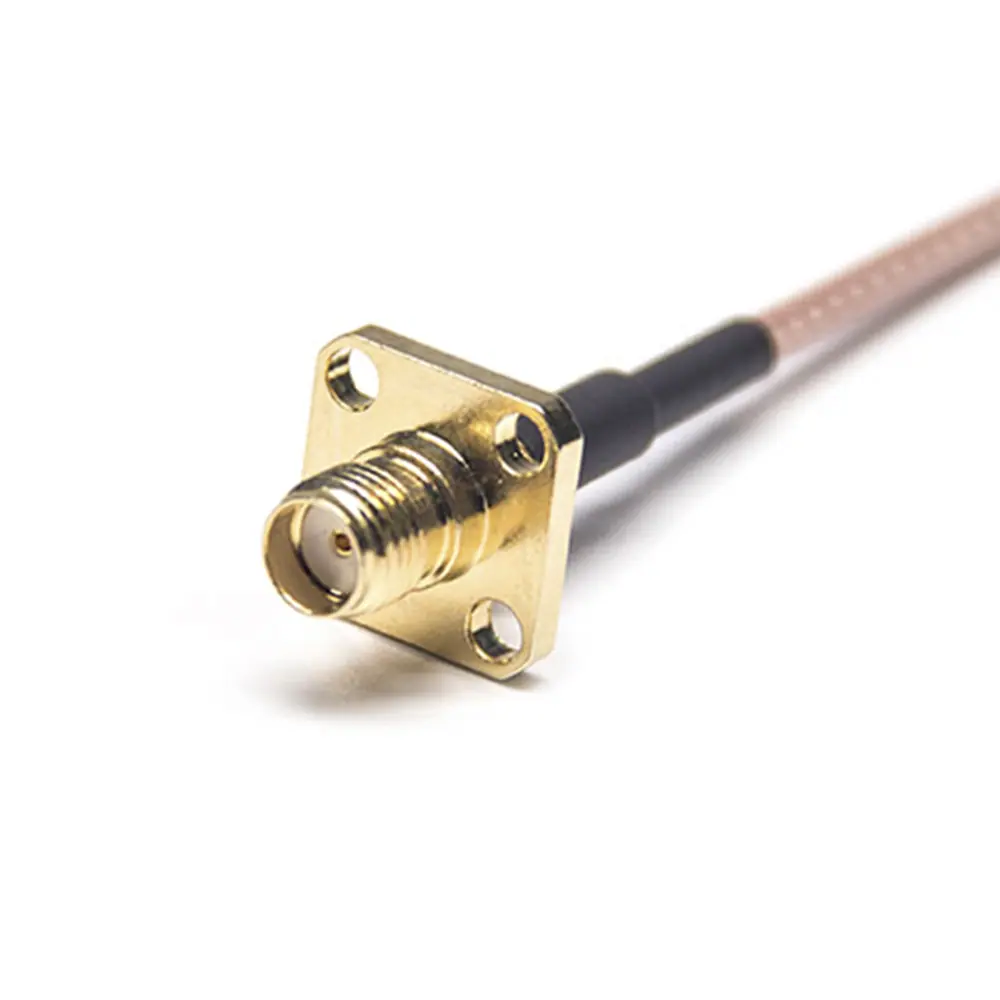

3. MCX Female Bulkhead Mount:

- Focus: Designed to pass through a panel or chassis.

- Advantage: Offers system isolation and often includes a weather seal. Useful for the input/output ports of an enclosed device.

3. Top MCX Connector Suppliers Recommended (Top 5 List)

In the competitive RF components market, selecting the right manufacturer is as important as selecting the right part number. Based on factors like quality assurance, frequency performance reports, and global supply chain reliability, here is a list of top suppliers for reliable MCX female connectors.

1. Amphenol Corporation

One of the world’s largest connector manufacturers, they are a major player in RF Coaxial Connectors through their specialized divisions like Amphenol RF. They are known for high-reliability, high-performance interconnects across various industries.

2. TE Connectivity (TE)

A global technology leader in connectivity and sensors. They offer a comprehensive portfolio of coaxial and RF connectors, including MCX connectors, often highlighted for their broad industrial, automotive, and data communication applications.

3. Molex (a Koch Industries Company)

A significant supplier of electronic and fiber optic interconnect solutions. Molex provides a wide range of RF connectors, including MCX jacks/sockets and plugs for various mounting types (PCB, cable).

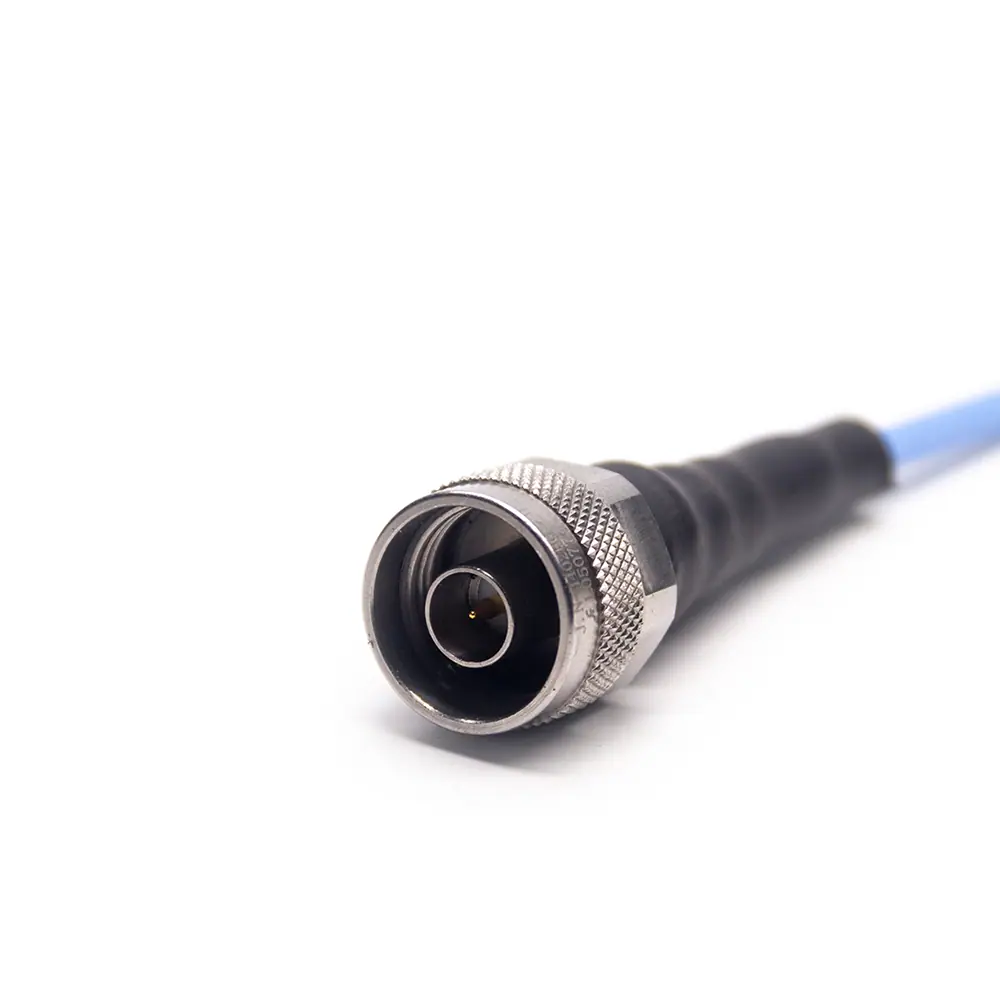

4. Rosenberger Group

A global leader specializing in impedance-controlled and optical interconnect solutions in high-frequency technology. They are highly regarded for their precision-engineered RF coaxial connectors, making them a top choice for demanding high-frequency applications like MCX.

5. Renhotec

Founded in 2008, Specializing in producing high-performance RF connectors, RF coax adapters, RF cables and Antennas. Have a professional manufacturing environment with stamping, moulding,injection moulding workshops and lathe turning, for each aspect and process are rigorously tested and controlled.

4. Common Troubleshooting and Installation Guidelines

Proper installation is paramount to achieving the published performance specifications of any MCX female connector. Errors in handling or assembly can introduce reflection and signal loss.

4.1 Essential Installation Tips

- Torque Control: The snap-on mechanism requires sufficient force to engage, but excessive force can damage the solder joints on a MCX female PCB mount or deform the center contact. While typically not torque-specified like threaded connectors, proper tool alignment is crucial.

- Cable Preparation: For cable-mount MCX female types, the stripping length and depth must be precise. Incorrect braid trimming is the leading cause of VSWR failure, as it changes the impedance near the mating interface.

- Visual Inspection: Always inspect the inner contact of the MCX female connector after installation for any signs of debris or bending before mating with the plug.

4.2 Troubleshooting VSWR and Continuity Failures

| Issue | Probable Cause | Quick Fix/Verification |

| High VSWR | Poor crimp/solder joint; Connector damage; Cable bend radius too tight. | Re-terminate the cable or replace the connector; Use a Vector Network Analyzer (VNA) to locate the fault. |

| Intermittent Signal | Wear on center contact; Mechanical degradation from excessive mating cycles. | Replace the MCX female connector (reached end-of-life); Verify mating cycle count. |

| No Continuity (DC) | Inner contact of the MCX female or the plug is bent or missing; Poor solder connection to the PCB trace. | Visual inspection; Check resistance from PCB trace to center contact using a multimeter. |

5. Frequently Asked Questions (FAQ)

Q: What is the main difference between MCX and MMCX connectors?

A: The primary difference is size. MMCX (Micro-Miniature Coaxial) connectors are significantly smaller than MCX, making them suitable for extremely dense packaging where space is the absolute constraint. However, MCX female connectors are generally easier to handle, disconnect, and have a more robust snap mechanism. MMCX is typically limited to even fewer mating cycles.

Q: Do MCX connectors support 75-ohm impedance?

A: Yes, 75Ω versions of the MCX female connector exist, but 50Ω is the standard and far more common type for most RF communication (Wi-Fi, GPS, cellular). If you require 75Ω for video applications, you must specifically source and verify the part number as 75Ω, as mixing standards leads to severe VSWR degradation.

Q: Can an MCX connector be used in outdoor or harsh environments?

A: Standard MCX female connectors are typically not rated for harsh environments. For outdoor use, you must specify a bulkhead MCX female connector version with a specified Ingress Protection (IP) rating (e.g., IP67 or IP68) which incorporates internal O-rings and sealing gaskets to protect against dust and moisture.

6. Contact Us for Tailored MCX Solutions

Whether you need high-volume, cost-effective MCX female PCB mount connectors or specialized low-PIM cable assemblies, our team of experts [email protected] is ready to provide tailored recommendations and sourcing assistance.