Introduction: An Essential Guide to MMCX Cable Assemblies

Micro-Miniature Coaxial (MMCX) connectors are a critical component in the vast landscape of Radio Frequency (RF) and microwave interconnect systems. Defined by their remarkably small size, lightweight construction, and reliable snap-on coupling mechanism, MMCX cable assemblies are indispensable in modern electronics where space and weight limitations are paramount.This in-depth guide is designed for engineers and procurement specialists. It will demystify the structure, detail the critical electrical specifications, and map the primary applications of MMCX cable assemblies, ensuring you make an informed choice for your next demanding project.

Foundational Knowledge of MMCX Cable Assemblies

MMCX connectors, first introduced in the 1990s, are designed to meet the growing demand for miniaturization in RF systems. They conform to the European CECC 22000 specification, ensuring standardization and interoperability across vendors. The key differentiating feature is the secure, yet simple, snap-on coupling, which permits 360-degree rotation, offering exceptional flexibility in PCB layouts and cable routing.

MMCX Connector Structure and Compliance

An MMCX cable assembly consists of the MMCX plug, the cable (e.g., RG-174), and often an MMCX jack or another connector type on the opposite end. The plug-and-jack design is based on the inner contact and insulator dimensions similar to the older SMB series, but the outer diameter is significantly smaller.

The connection mechanism relies on friction and an optimized engagement force (typically Max. 18N) and separation force (Min. 6N), providing high retention force without the need for cumbersome threading found in SMA connectors.

The Core Advantages and Limitations of MMCX

MMCX Cable Assembly Types and Key Specifications

Selecting the correct MMCX cable assembly hinges on understanding the connector variants and the stringent electrical specifications that guarantee signal integrity at high frequencies. All standard MMCX connectors are designed for a nominal impedance of 50 ohms.

Electrical Performance Specifications Detailed

The performance of an MMCX cable assembly is largely defined by its electrical specifications, particularly at its maximum operating frequency (typically DC to 6 GHz).

MMCX Connector Variants

- Standard MMCX: Features a standard interface (male inner contact/female outer contact).

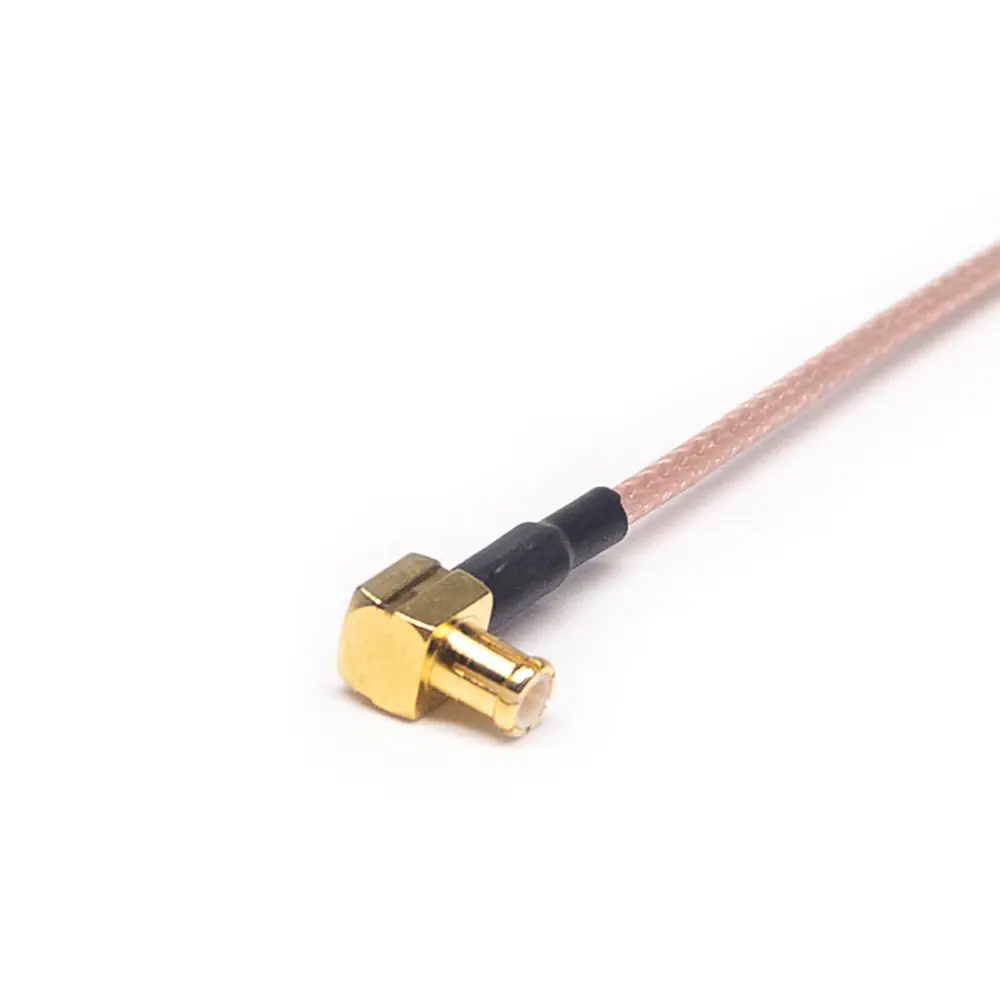

- Right-Angle MMCX: Ideal for applications where the cable must exit the PCB surface parallel to the board, saving vertical space.

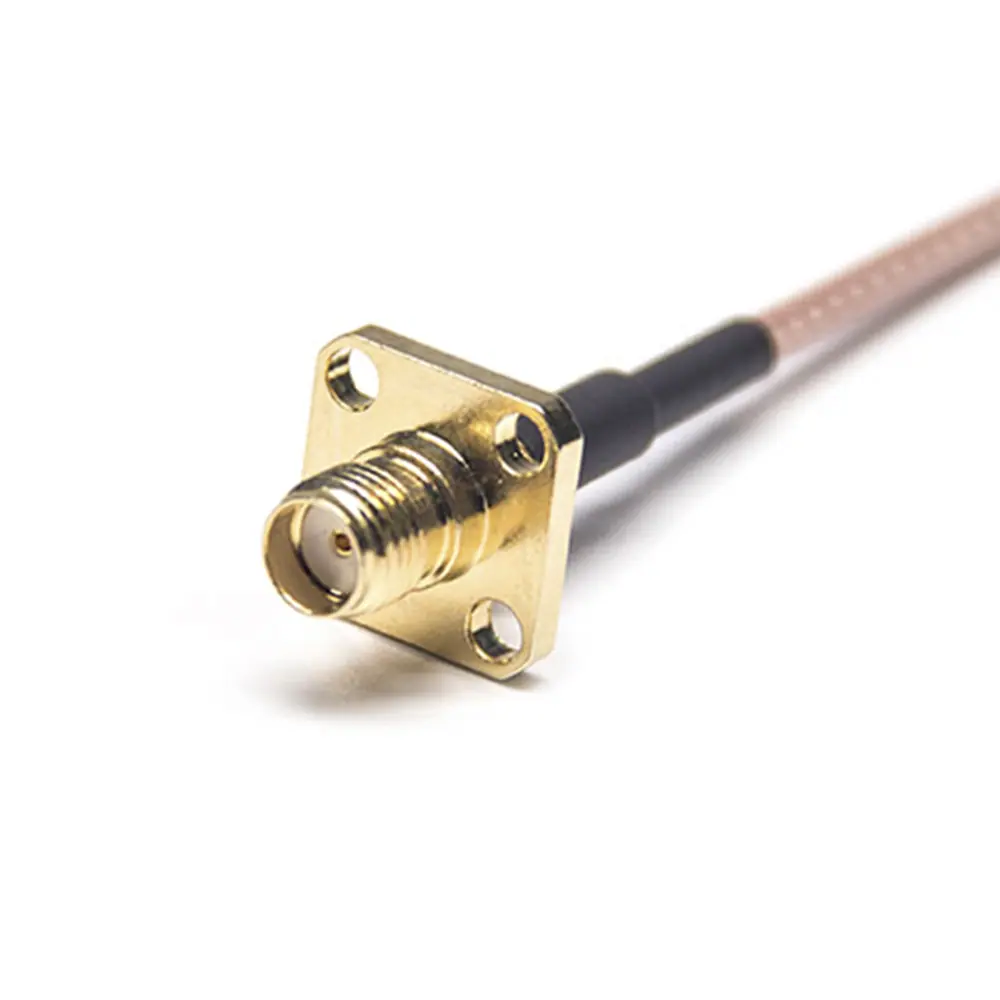

- Bulkhead MMCX: Designed for mounting on a panel or enclosure, providing an interface point.

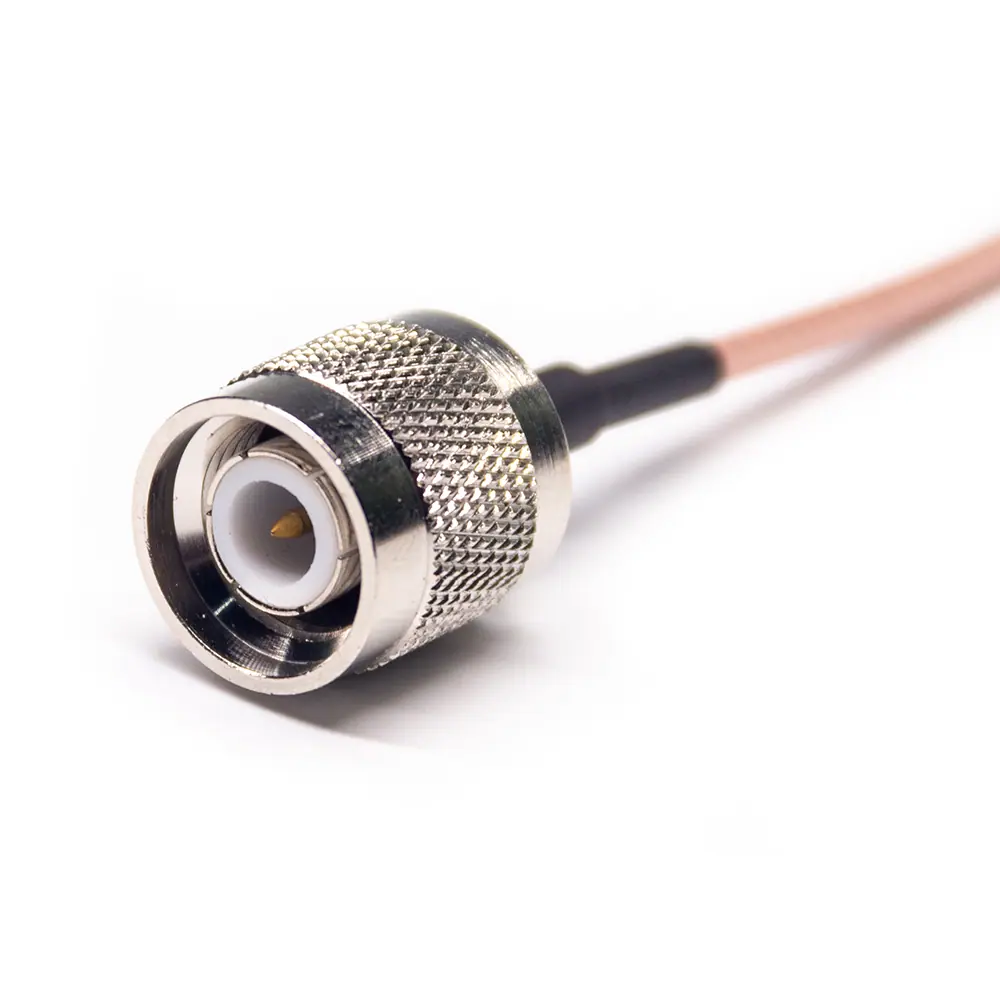

- Reverse Polarity MMCX (RP-MMCX): The internal mating interface is reversed (e.g., the plug has the female contact). This is primarily used to prevent connection with standard MMCX parts, often for regulatory compliance in specific wireless applications.

Compatible Cable Types for MMCX Assemblies

The physical size of the MMCX connector necessitates the use of microminiature, flexible coaxial cables. The most common cables paired with the MMCX connector are from the RG-series, known for their small diameter and flexibility.

Typical Application Scenarios for MMCX Cable Assemblies

The compact form factor and DC to 6 GHz frequency range make MMCX cable assemblies highly versatile across several key high-growth sectors.

Wireless Communication Equipment

MMCX is the standard choice for internal and external antenna connections in various portable wireless devices.

- GPS Receivers and Navigation Systems: Used to connect external antennas to GPS modules in automotive, marine, and drone (UAV) applications. The small footprint and 360°rotation simplify installation in tight vehicle dashboards or airframes.

- Wi-Fi and Bluetooth Modules: Common in embedded systems, PC/LAN cards, and consumer routers for internal antenna leads due to their minimal space requirement.

- Small Cell and Micro Base Stations: In densely populated environments, the miniaturization trend drives the use of MMCX to connect RF circuits to the antenna arrays inside small cell enclosures, operating within the sub-6 GHz spectrum.

Industrial and Medical Equipment

Beyond telecommunications, MMCX offers a robust solution for highly sensitive, space-constrained environments.

- Portable Test and Measurement Instruments: Used for connecting probes or antennas to handheld spectrum analyzers and RF signal generators where flexibility and size are crucial.

- Medical Devices: The lightweight nature makes MMCX ideal for patient-worn or portable medical monitors, diagnostic tools, and especially in hearing aids, where the connectors must be nearly invisible.

- IoT and Micro Sensors: Connecting micro-antennas in dense Internet of Things (IoT) nodes and sensor arrays that demand high reliability in miniature packages

How to Select and Source High-Quality MMCX Cable Assemblies

Choosing a reliable supplier is as crucial as specifying the correct parameters. Quality is paramount, as an improperly terminated MMCX cable assembly can introduce significant VSWR and insertion loss, crippling the system’s performance.

- Check Certification and Compliance: Ensure the manufacturer adheres to industry standards (e.g., CECC 22000 and RoHS/REACH compliance).

- Verify Termination Precision: Demand suppliers utilize precision soldering and crimping tools and conduct 100% electrical testing, including VSWR sweep testing, on finished assemblies to guarantee performance up to the specified frequency.

- Specify Material Quality: The body should be brass with gold plating, and the insulator should be PTFE (Teflon) for optimal electrical characteristics and temperature tolerance.

Related Products

MMCX to Fakra Cable Assemblies

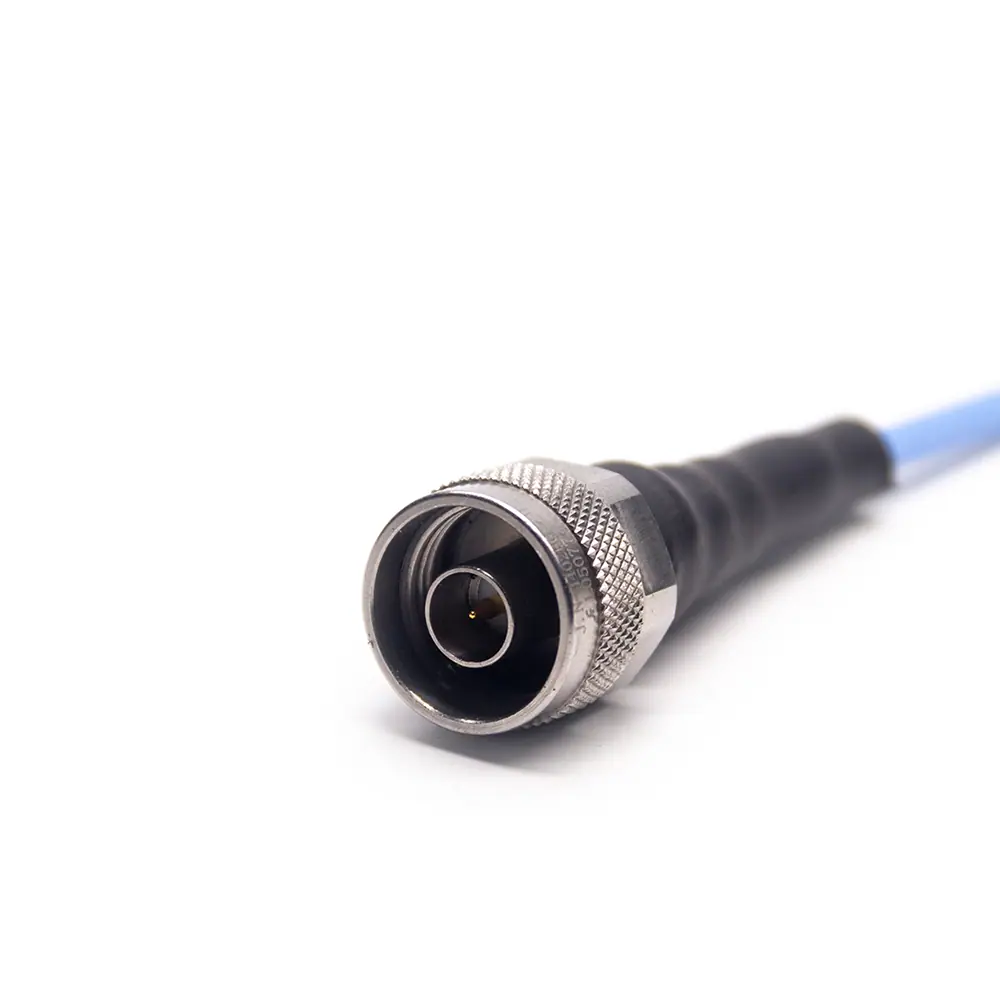

MMCX to N Type Cable Assemblies

Frequently Asked Questions (FAQ)

- Q: What is the main difference between MMCX and U.FL (or IPEX/MHF)?

- A: Both are micro-miniature RF connectors. MMCX is semi-locking (snap-on) and provides a higher-rated durability (500 cycles), typically supporting up to 6 GHz. U.FL is a non-locking, lower-profile connector with lower durability (typically 30 cycles), often used for board-level internal connections where a permanent, low-profile fit is needed.

- Q: Can MMCX handle signals higher than 6 GHz?

- A: Standard MMCX connectors are rated for DC to 6 GHz (Max. VSWR≤1.25:1). While some high-performance variants can reach 8 GHz, systems operating consistently above 6 GHz should consider a smaller, high-frequency connector series like 2.92mm or higher-grade SMA.

- Q: How does cable length affect MMCX performance?

- A: Shorter cable runs are always preferred. Longer cables introduce greater insertion loss, especially with small-diameter cables like RG-174. For runs over 3 feet (1 meter) at high frequencies, upgrading to a lower-loss cable (like RG-316 or specialized LMR alternatives) is necessary to maintain signal integrity.