Introduction: Navigating Miniaturization and Performance

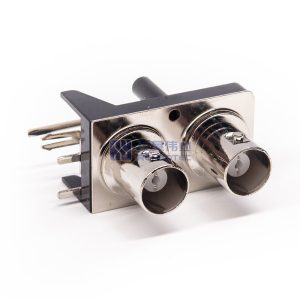

The relentless advance of technology presents a clear challenge for system designers: integrating more functionality into shrinking spaces while simultaneously demanding higher signal speeds and unwavering stability. This push for greater power in a smaller footprint finds a compelling answer in the evolution of a classic component: the BNC connector family.

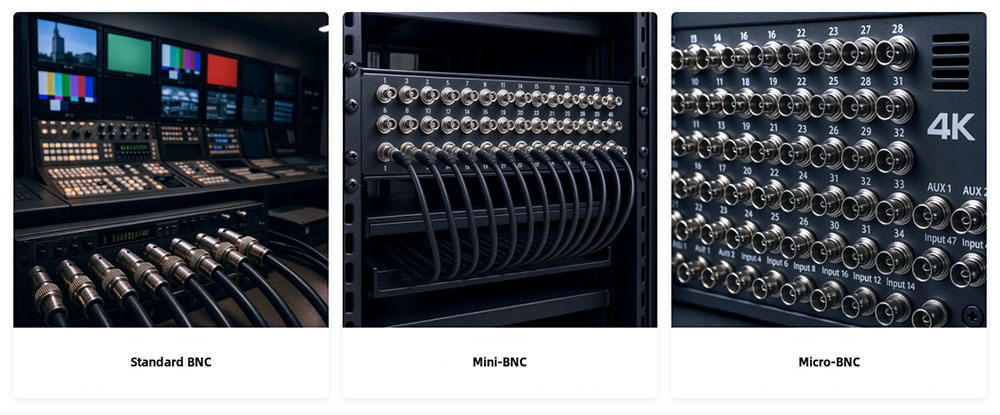

From the broadcast studio transmitting 4K/8K video to the 5G base station handling massive data streams, the choice of connector is critical. This article explores the core differences between Standard, Mini, and Micro-BNC connectors, providing a clear guide to selecting the optimal solution for modern, high-density applications.

Quick overview of key comparison points:

Standard BNC Connectors: The Proven Foundation

To understand the innovations of miniaturized BNCs, we must first return to the origin: the classic design that became an industry cornerstone. BNC stands for Bayonet Nut Connector, a name that vividly describes its iconic “push-and-twist” locking mechanism. Its creation is credited to two brilliant engineers, Paul Neill of Bell Labs (inventor of the N-type connector) and Carl Concelman of Amphenol (inventor of the C-type connector). The foundational design was based on a patent for a coaxial cable connector that minimized wave reflection, filed in 1945 by Octavio M. Salati.

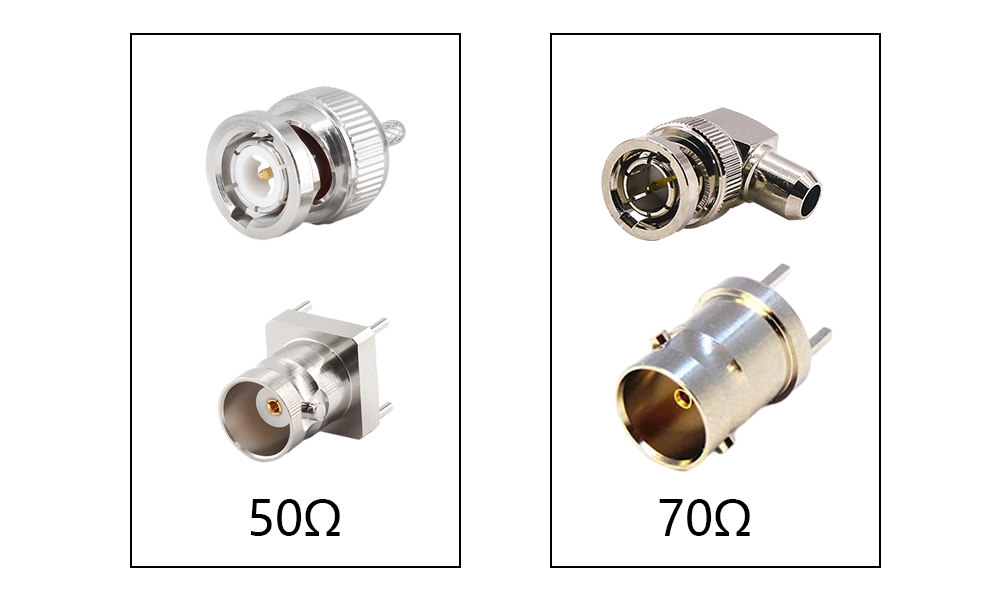

This simple construction, consisting of a center pin, an insulator, and a metal shell with a reliable bayonet lock, provides excellent electromagnetic shielding and mechanical stability. Technically, the most crucial characteristic of the standard BNC is its availability in two primary characteristic impedances:

- 50Ω (50 Ohm): Primarily used for radio frequency (RF) applications, such as wireless communication systems, early computer networks (Ethernet), and various types of test equipment.

- 75Ω (75 Ohm): Optimized for video signal transmission, making it the go-to interface for analog video, standard-definition (SD-SDI), and high-definition (HD-SDI) digital video signals.

However, being a classic also implies limitations. The standard BNC connector was designed for a frequency range typically up to 4 GHz, which presents a performance ceiling for burgeoning high-frequency applications like 12G-SDI.

Market Drivers: Why Miniaturization Became Essential

Technological evolution is never arbitrary; it is a direct response to market demands. The move toward BNC miniaturization was powerfully driven by several key industry trends:

- The Ultra-HD Revolution in Broadcasting: As 4K/8K video production became mainstream, 12G-SDI emerged as the standard for baseband signal transport. This requires transmitting a massive 12Gbps of data over a single cable. Traditional BNC interfaces not only struggled with the frequency demands but their large size also made high-density deployment on switchers, routers, and capture cards an impossibility.

- Precision and Portability in Medical Devices: Modern medical imaging systems, such as HD endoscopes, surgical robots, and ultrasound probes, require the integration of numerous high-performance connections within extremely confined spaces. Connectors must shrink in size and weight while guaranteeing signal integrity.

- The Proliferation of 5G and IoT: 5G base stations and edge computing devices need to accommodate a large number of RF units within compact chassis, placing unprecedented demands on connector density and high-frequency performance.

It was against this backdrop that Mini-BNC and Micro-BNC were born. Their objective was crystal clear: deliver higher performance in a smaller package.

Side-by-Side: Key Specifications Compared

A direct technical comparison reveals the clear evolutionary path from the standard to the micro form factor. The table below summarizes the fundamental differences that guide the selection process.

The evolutionary path is clear from the table: sacrificing the universality of 50Ω to focus on 75Ω for video and high-frequency applications, while drastically compressing size and significantly boosting frequency performance.

Application Guide: Matching Connector to Use Case

Selecting the correct BNC type requires aligning specifications with the practical realities of the application. The wrong choice can lead to performance loss, physical incompatibility, or unnecessary cost.

Standard BNC: The Enduring Workhorse

Despite the emergence of new options, the standard BNC remains indispensable in many fields due to its high ubiquity, robustness, and cost-effectiveness.

- Best-Fit Scenarios:

- Traditional analog and HD CCTV surveillance systems.

- Lab test equipment and signal generators where space is not a constraint.

- Signal connections in industrial automation and control systems.

- Maintenance and connection of legacy broadcast equipment.

Choose it when: Your project is cost-sensitive, has no strict space limitations, and operates at frequencies below 4 GHz. Standard BNC is the most reliable and economical choice.

Mini-BNC: The Balanced Performer for Upgrades

The Mini-BNC serves as an excellent “intermediate solution.” It offers a significant size reduction while providing the capability to support 12G-SDI.

- Best-Fit Scenarios:

- Telecom equipment racks and patch panels where space is becoming limited.

- Upgrading existing systems to higher bandwidths.

- High-density digital audio routers.

Tips: In the market, Mini-BNC is sometimes mentioned alongside the DIN 1.0/2.3 connector. While they can be interchangeable in 75Ω applications, their locking mechanisms differ: Mini-BNC is typically bayonet-style, whereas DIN 1.0/2.3 uses a push-pull lock. Be mindful of physical compatibility during selection.

Micro-BNC: The High-Density Champion

This is the connector truly engineered for modern high-density, high-frequency applications. Pioneered and promoted by industry leader Amphenol, the Micro-BNC (often marketed as HD-BNC) is the de facto standard for miniaturized BNCs today.

- Best-Fit Scenarios:

- 4K/8K Broadcast Equipment: Cameras, video switchers, servers, monitors, and high-density capture cards, perfectly matching 12G-SDI requirements.

- Precision Medical Imaging Systems: Endoscopes, surgical robots, and ultrasound equipment, meeting miniaturization needs without compromising signal fidelity.

- 5G Communications & Data Centers: Used for receiving and distributing high-density RF signals.

Choose it when: Your design real estate is extremely valuable, interface density is paramount, and you must reliably transmit signals at 12 GHz or higher. Micro-BNC is the undisputed best choice.

Beyond Basic Specs: Critical Selection Factors

A seasoned engineer knows that selection goes far beyond the spec sheet. To ensure the long-term stability of your project, you must also consider these “intangible” factors:

Mating Cycles Performance:

- Standard BNC: Typically rated for 500-1,000 mating cycles with gold-plated contacts. The robust bayonet mechanism and larger contact area make it ideal for test equipment that sees frequent reconnections, such as oscilloscopes and signal generators in R&D labs.

- Mini-BNC: Generally supports 300-500 mating cycles due to smaller contact surfaces. Best suited for semi-permanent installations like telecom patch panels where connections change monthly rather than daily.

EMI Shielding Effectiveness:

- Standard BNC: Provides 60-80dB shielding effectiveness up to 1GHz, with performance degrading at higher frequencies. The larger metal shell offers excellent low-frequency protection but becomes less effective as signal frequency approaches 4GHz.

- Mini-BNC: Advanced designs achieve 65-75dB shielding across the full 12GHz range. The reduced size actually helps maintain consistent impedance, making it superior to standard BNC for high-frequency applications.

- Micro-BNC: Top-tier models deliver 70-85dB shielding effectiveness up to 18GHz. The precision-machined housing and advanced plating (often silver-plated copper) provide exceptional protection against crosstalk in dense 12G-SDI routing environments.

Termination Process & Tooling:

- Standard BNC: Uses widely available RG-59/RG-6 crimping tools (typically $50-200). The larger connector body is forgiving of minor crimping variations, making field installation straightforward.

- Mini-BNC: Requires specialized precision crimping tools ($300-800) due to smaller dimensions. However, the process remains similar to standard BNC, reducing training requirements for technicians.

- Micro-BNC: Demands high-precision assembly tools ($800-2,000+) and often benefits from factory termination. The tiny contact area means even minor crimping errors can cause significant signal degradation or mechanical failure.

Real-World Selection Matrix:

Tips: When evaluating suppliers, request actual test data for insertion loss, return loss, and shielding effectiveness at your operating frequency. Generic datasheets often show “typical” rather than “guaranteed” performance, which can lead to costly surprises in production.

FAQ

- Q: Can I use a 75Ω BNC connector in a 50Ω system?

A: This is strongly discouraged. An impedance mismatch will cause significant signal reflection and loss (return loss), especially in high-frequency applications. This will severely degrade signal quality and could even damage your equipment. Always ensure the impedance of the connector, cable, and device are matched.

- Q: Are HD-BNC and Micro-BNC the same thing?

A: Essentially, yes. HD-BNC is the registered trademark that Amphenol uses for its line of Micro-BNC products. Due to their market leadership, HD-BNC has become synonymous with high-quality Micro-BNC connectors, and the terms are often used interchangeably in the industry.

- Q: Do I need special tools to terminate cables with Mini-BNC or Micro-BNC connectors?

A: Yes. Due to their smaller size, you must use higher-precision crimping and stripping tools specifically designed for them. Using mismatched tools will result in an unreliable connection, compromising both electrical performance and mechanical

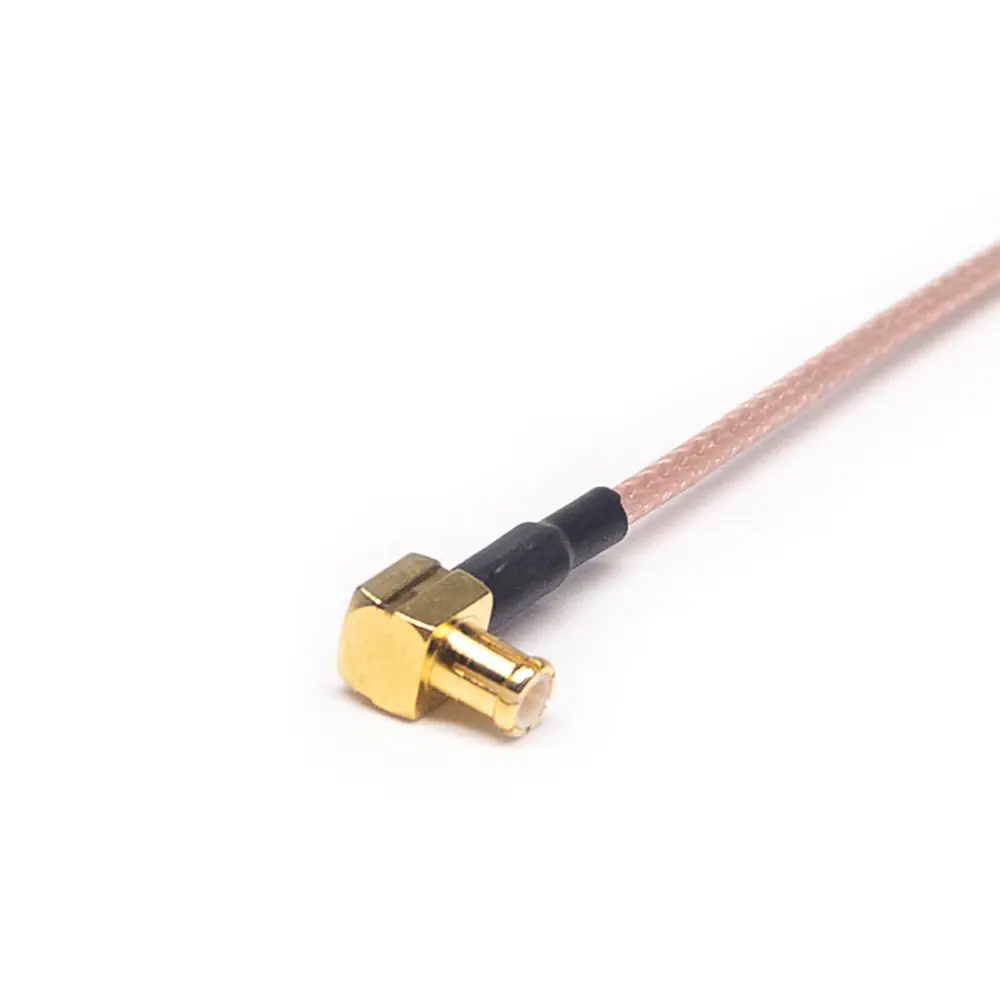

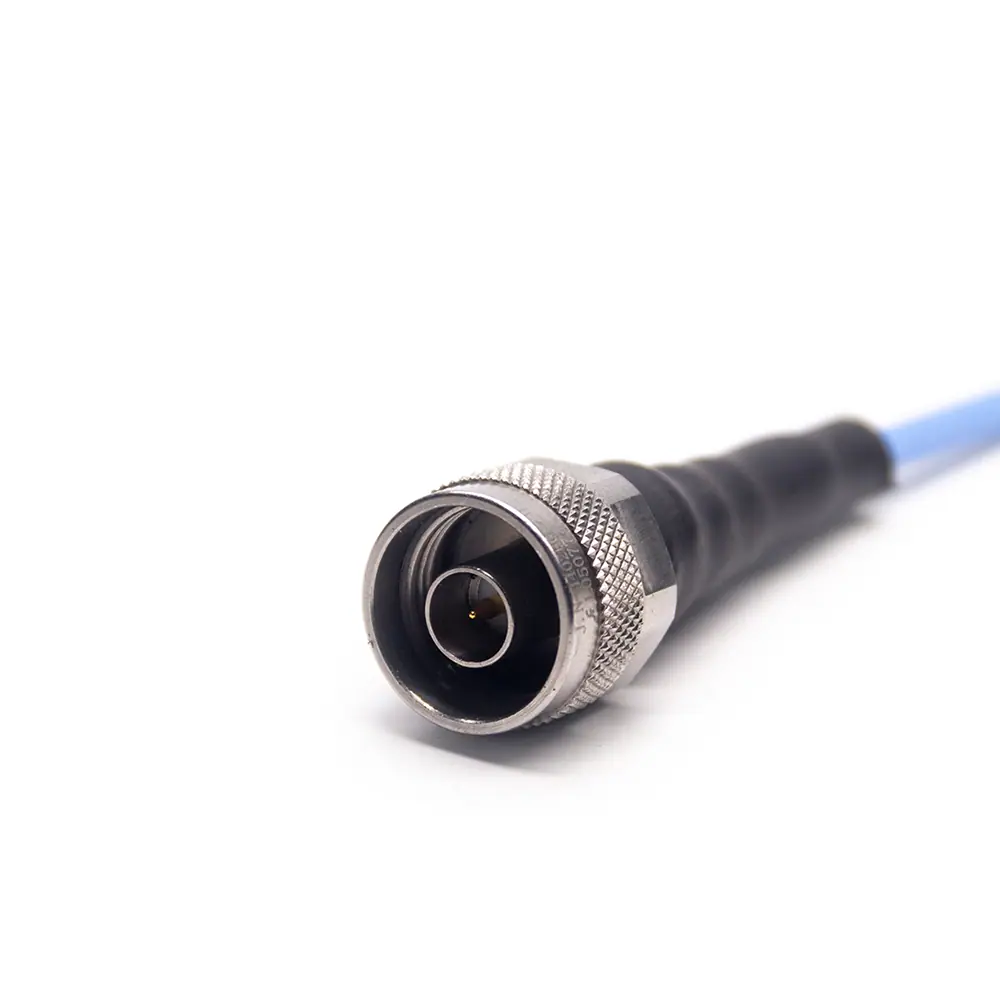

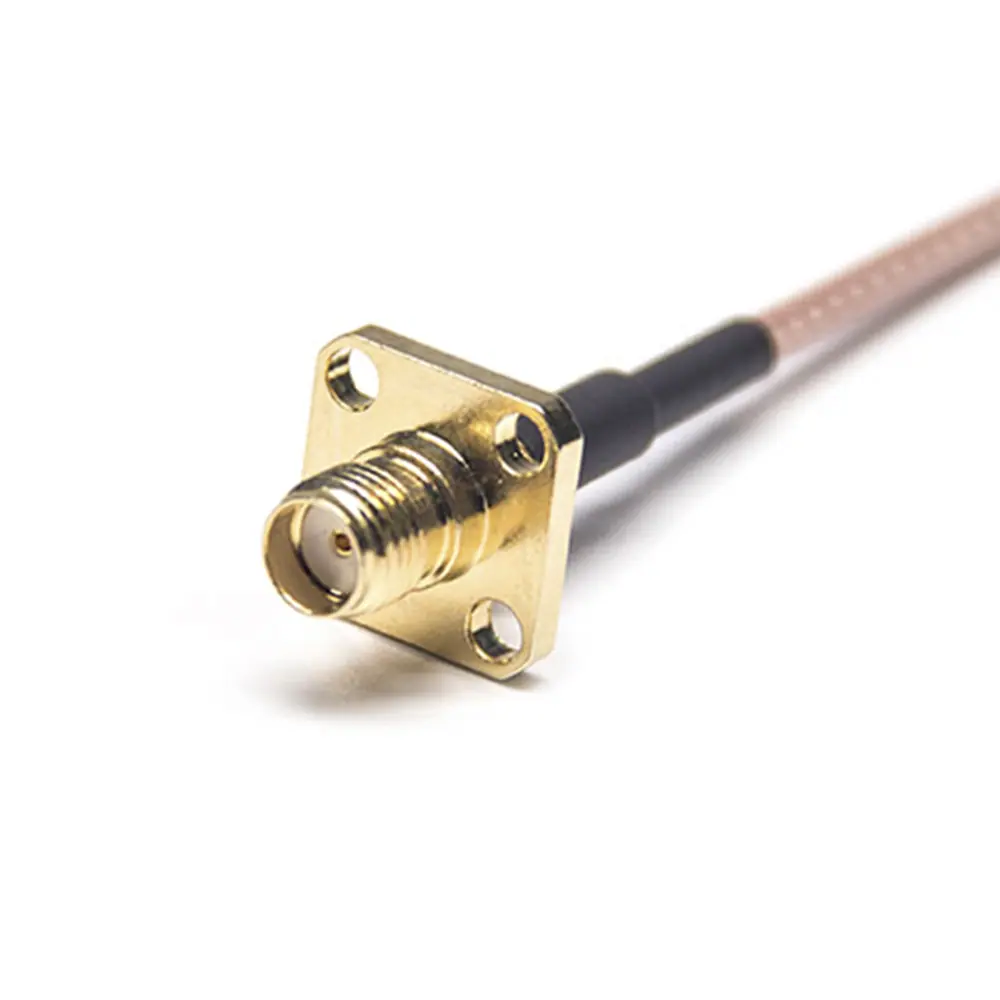

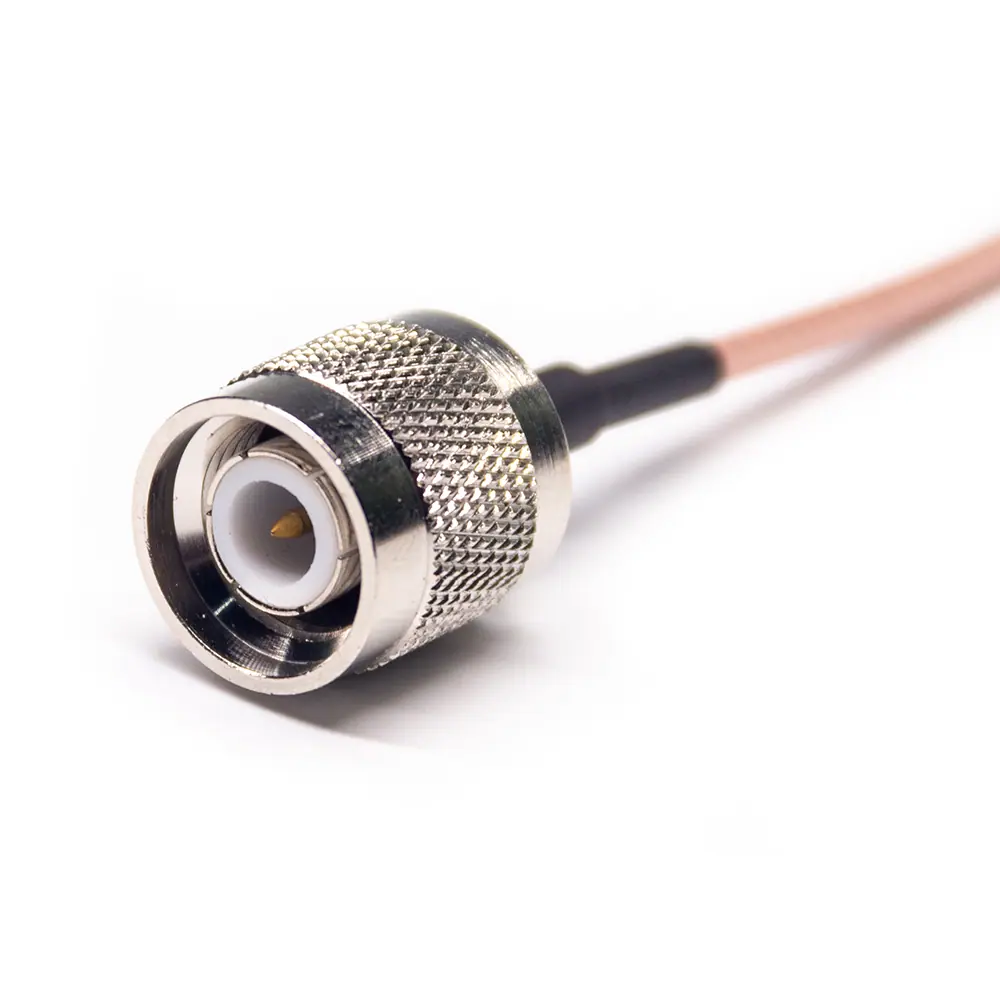

Related Connectors

Contact Us

Find Your Reliable Video & RF Connection Solution

Selecting the right coaxial connector is essential for maintaining signal integrity in video, broadcast, and mid-frequency RF applications. Whether you need standard BNC connectors for robust bayonet-locking in broadcast and test equipment, or high-density Mini-BNC and Micro-BNC solutions for 12G-SDI video and compact systems, our engineering team has the expertise to meet your needs.

Contact our connectivity specialists at [email protected] to discuss your BNC connector requirements, request custom configurations, and explore our full RF Catalog!