- The Naming Convention Decoded: It’s All About the Diameter

- A Deep Dive into Precision Connectors: Specs and Applications

- The Workhorse: SMA Connector (DC – 18 GHz)

- The Precision Upgrade: 3.5mm Connector (DC – 34 GHz)

- The Millimeter-Wave Staple: 2.92mm Connector (DC – 40 GHz)

- The High-Frequency Performer: 2.4mm Connector (DC – 50 GHz)

- The E-Band Expert: 1.85mm Connector (DC – 67 GHz)

- The Frontier: 1.0mm Connector (DC – 110 GHz)

- What Mates Safely (and What Doesn’t)

- Understanding Connector Grades for Optimal Results

- Frequently Asked Questions (FAQ)

- Your Partner in Precision Connectivity

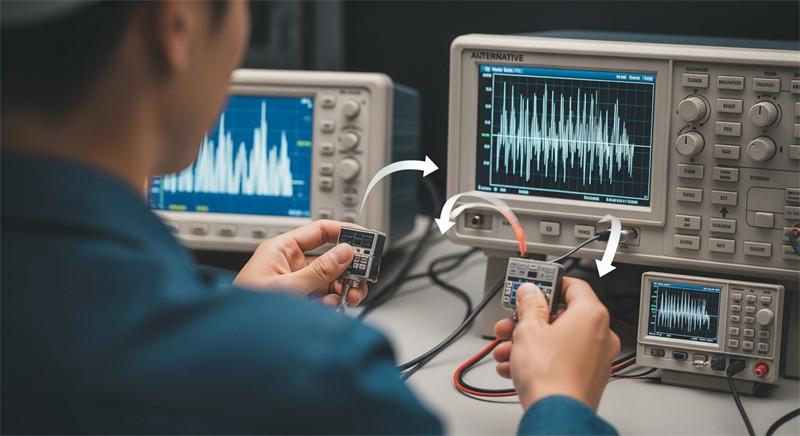

You’re a hardware engineer, staring at the back of a $100,000 vector network analyzer. You need to connect a new device under test (DUT) for a high-speed SerDes compliance check. In your hand is a cable, and on the panel is a port. They look almost identical—both are small, threaded, and gold-plated. You think, “It’s probably just another SMA.” But a moment of hesitation stops you. What if it’s a 3.5mm? Or a 2.92mm?

This scenario is all too common. In the world of high-frequency electronics, mistaking one precision coaxial connector for another is more than just an inconvenience; it can be a catastrophic, budget-breaking failure. A single incorrect mating can permanently damage the delicate internal structures of a precision connector, leading to skewed measurements, increased signal reflection, and, in the worst case, a costly repair for your high-end test equipment.

This guide is your definitive resource to end the confusion. We will demystify the key differences between these visually similar connectors, explain the rules of compatibility, and provide best practices to ensure you make the right connection, every time.

The Naming Convention Decoded: It’s All About the Diameter

The first step to mastering these connectors is understanding their names. While designations like “K-Type” or “V-Type” exist, the primary naming convention is brilliantly simple: the name corresponds to the inner diameter of the connector’s outer conductor, measured in millimeters.

For instance, a 2.4mm connector has an outer conductor with an inner diameter of precisely 2.4 millimeters. This dimension is critical because it defines the geometry of the coaxial structure, which in turn dictates the connector’s maximum operating frequency. As a general rule, a smaller diameter allows for a higher cutoff frequency, enabling the transmission of faster signals with greater fidelity.

The space between the center conductor and this outer conductor is filled with a dielectric material—either a solid plastic like Polytetrafluoroethylene (PTFE, or Teflon) or, in higher-performance connectors, primarily air. This distinction is a key factor in both electrical performance and mechanical durability.

A Deep Dive into Precision Connectors: Specs and Applications

While they may look similar from a distance, each of these connector series was designed for a specific performance tier. Below is a detailed breakdown of each type, from the ubiquitous SMA to the cutting-edge 1.0mm.

| Connector | Alias(es) | Max Frequency | Dielectric | Key Characteristics |

|---|---|---|---|---|

| SMA | SubMiniature ver. A | 18 GHz | PTFE (Teflon) | Robust, cost-effective, widely used. |

| 3.5mm | – | 34 GHz | Air | Mechanically robust, better repeatability than SMA. |

| 2.92mm | K Connector, SMK | 40 GHz | Air | Excellent performance, industry workhorse for mmWave. |

| 2.4mm | – | 50 GHz | Air | Rugged walls, for high-frequency systems. |

| 1.85mm | V Connector | 67 GHz | Air | Excellent for E-band and millimeter-wave comms. |

| 1.0mm | W Connector | 110 GHz | Air | For leading-edge test & measurement up to W-band. |

The Workhorse: SMA Connector (DC – 18 GHz)

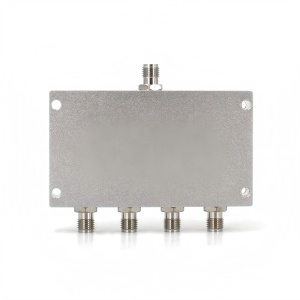

The SubMiniature version A (SMA) connector is arguably the most recognized RF connector in the world. Developed in the 1960s, its robust design and use of a solid PTFE dielectric make it a reliable and cost-effective choice for a vast range of applications up to 18 GHz, including Wi-Fi systems, antennas, and general-purpose RF devices.

The Precision Upgrade: 3.5mm Connector (DC – 34 GHz)

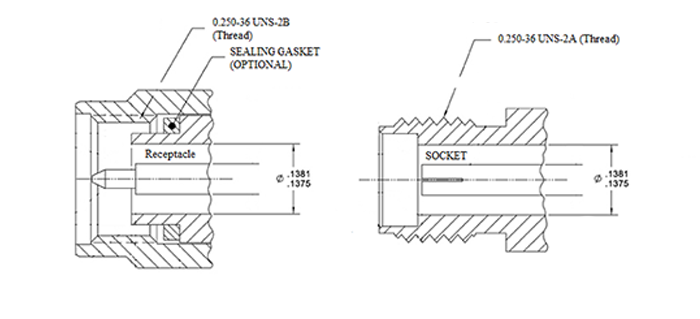

At first glance, a 3.5mm connector looks like a higher-quality SMA. The key difference lies inside: the 3.5mm connector uses an air dielectric. This eliminates the performance inconsistencies associated with the Teflon interface in SMAs. Furthermore, its outer conductor wall is thicker, giving it superior mechanical strength and durability. This makes the 3.5mm connector a favorite for laboratory and test applications where repeatable measurements are paramount.

The Millimeter-Wave Staple: 2.92mm Connector (DC – 40 GHz)

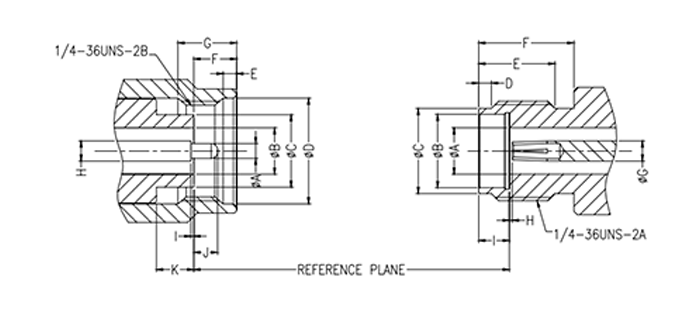

Often called the “K Connector” (a trademark of Anritsu), the 2.92mm connector was a game-changer, opening up reliable coaxial measurements to 40 GHz. It offers excellent electrical performance and, crucially, is mechanically compatible with SMA and 3.5mm connectors. This compatibility has made it one of the most widely adopted millimeter-wave connectors in microwave communication, aerospace, and high-speed digital testing.

The High-Frequency Performer: 2.4mm Connector (DC – 50 GHz)

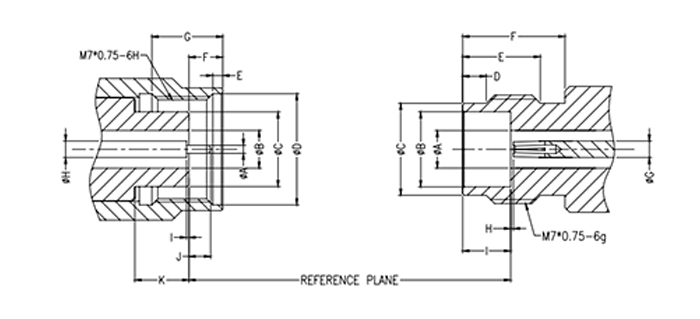

Pushing the frequency boundary to 50 GHz, the 2.4mm connector features a more rugged construction with thicker walls compared to its higher-frequency cousins. This provides increased durability. It is critical to note that 2.4mm connectors are NOT mechanically compatible with the SMA/3.5mm/2.92mm family. Attempting to mate them will cause immediate and permanent damage.

The E-Band Expert: 1.85mm Connector (DC – 67 GHz)

Known as the “V Connector” (a trademark of Anritsu), the 1.85mm connector enables precise measurements up to 67 GHz. Its development was a significant step for applications in the V-band and E-band, such as automotive radar, satellite communications, and millimeter-wave systems. It is mechanically compatible with the 2.4mm connector.

The Frontier: 1.0mm Connector (DC – 110 GHz)

Representing the pinnacle of coaxial connector technology, the 1.0mm connector (or “W Connector”) supports transmission modes up to an astonishing 110 GHz. Its manufacturing requires immense precision, and it is used in the most advanced research, development, and metrology applications, enabling the next generation of high-frequency technologies.

What Mates Safely (and What Doesn’t)

This is the most critical section of the guide. Answering the core questions: Is SMA compatible with 3.5 mm? and Are SMA and 3.5 mm the same? The answer is nuanced. They are not the same, but they are mechanically compatible for mating.

However, “mechanically compatible” does not mean “electrically ideal” or “risk-free.” Connectors can be grouped into families that share the same physical thread size and basic interface dimensions. Mating within a family is possible, but mating across families is destructive.

| Mates With ▼ | SMA (Male) | 3.5mm (Male) | 2.92mm (Male) | 2.4mm (Male) | 1.85mm (Male) |

|---|---|---|---|---|---|

| SMA (Female) | ✅ | ⚠️ | ⚠️ | ❌ | ❌ |

| 3.5mm (Female) | ⚠️ | ✅ | ✅ | ❌ | ❌ |

| 2.92mm (Female) | ⚠️ | ✅ | ✅ | ❌ | ❌ |

| 2.4mm (Female) | ❌ | ❌ | ❌ | ✅ | ✅ |

| 1.85mm (Female) | ❌ | ❌ | ❌ | ✅ | ✅ |

Understanding the Symbols:

- ✅ Safe & Recommended: The connectors are fully compatible and the connection will perform as expected for the given connector types.

- ⚠️ Caution – Performance & Damage Risk: While mechanically possible, this connection is not recommended. It presents risks of either physical damage or significant performance limitation. See the two cases below.

- ❌ Incompatible – DO NOT MATE: These connectors have different physical dimensions and threads. Attempting to connect them will cause immediate and permanent damage.

The Two Critical “Warning” Scenarios (⚠️):

High-Grade Male into Low-Grade Female (e.g., 3.5mm Male ➔ SMA Female): This poses a high risk of performance degradation. While less likely to cause damage, the connection’s performance (maximum frequency, insertion loss, VSWR) will be severely limited by the lower-grade SMA female. You are effectively downgrading your precision connector to SMA performance. There is also a risk of transferring contaminants from the less-clean production-grade connector to the pristine surface of the precision male connector.

Low-Grade Male into High-Grade Female (e.g., SMA Male ➔ 3.5mm Female): This poses a high risk of physical damage. The wider manufacturing tolerances of the SMA male’s center pin can bend, deform, or permanently damage the delicate, precision-engineered collet (the internal spring fingers) of the 3.5mm or 2.92mm female connector.

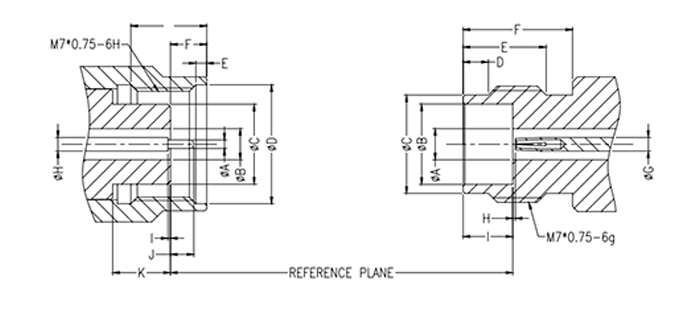

The Two Main Mating Groups:

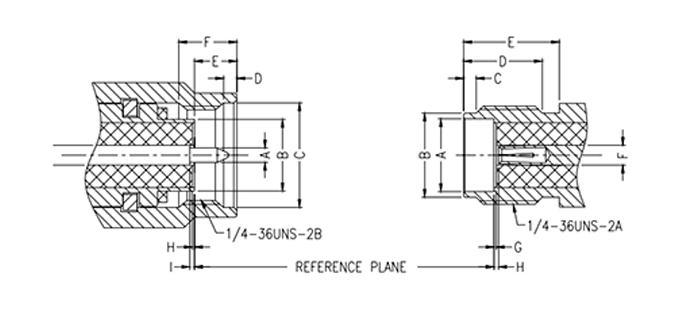

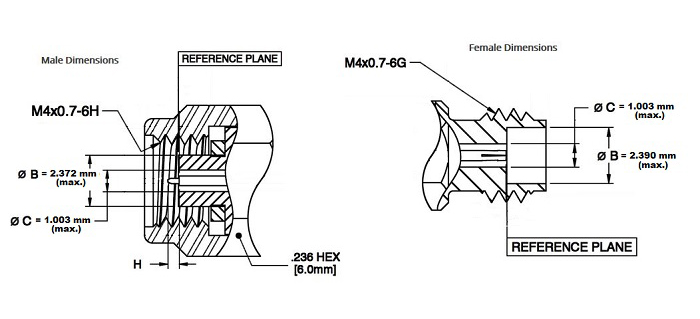

- Group 1 (1/4-36UNS Thread): SMA, 3.5mm, 2.92mm

- Group 2 (M7 x 0.75 Thread): 2.4mm, 1.85mm

Never attempt to cross-mate a connector from Group 1 with one from Group 2.

Understanding Connector Grades for Optimal Results

Not all connectors of the same type are created equal. They are typically manufactured in three distinct grades, balancing performance, durability, and cost.

- Metrology Grade: The highest tier. Used for calibration and verification standards. They feature the tightest tolerances, often a slotless female center conductor, and an air dielectric for maximum accuracy and repeatability. They are expensive and should be handled with extreme care.

- Instrument Grade: A “middle tier” found on the front panels of high-performance instruments and in high-quality test cables. They offer excellent performance and long life but may not have the ultimate precision of metrology grade.

- Production Grade: The lowest cost and most common grade. Found on components, DUTs, and general-purpose cables. They have wider tolerances and a limited number of mating cycles.

The Golden Rule: Never connect a low-grade connector directly to a high-grade one. A poorly-made production-grade male connector can instantly ruin an expensive metrology-grade female port. Always use a high-quality, sacrificial “connector saver” adapter on your instrument ports to protect them from the wear and tear of daily use.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between an SMA and a 3.5mm connector?

A: While they are mechanically intermateable, the primary difference is the dielectric material. SMAs use a solid PTFE (Teflon) dielectric, while 3.5mm connectors use a more precise air dielectric. This gives the 3.5mm connector better performance up to 34 GHz and higher mechanical durability.

Q2: Can I plug a 2.92mm connector into an SMA jack?

A: Yes, you can. The 2.92mm, 3.5mm, and SMA connectors are all part of the same mechanically compatible family. However, be aware that the lower precision of the SMA female jack could slightly compromise the performance of the connection, and repeated matings can cause wear.

Q3: Why are 2.4mm connectors not compatible with the SMA family?

A: They belong to completely different physical design families. The 2.4mm connector uses a different thread size (M7) than the SMA family’s imperial thread (1/4-36UNS). Their internal dimensions are also completely different. Attempting to force them together will destroy both connectors.

Q4: What is an RP-SMA connector and is it compatible with SMA?

A: RP-SMA stands for Reverse Polarity SMA. In an RP-SMA, the gender of the center conductor is swapped. The male body has a female socket (a hole), and the female body has a male pin. They are not compatible with standard SMA connectors and will not make an electrical connection.

Your Partner in Precision Connectivity

Navigating the world of high-frequency connectors can be complex, but understanding the fundamental differences in design, compatibility, and quality is the first step toward flawless measurements and protecting your valuable equipment. By following the guidelines for identification, mating, and handling, you can ensure reliable, repeatable results for years to come.

If you still have questions about selecting the right connector for your specific application, or if you need high-performance, reliable connectors and cable assemblies you can trust, our team of experts([email protected]) is here to help.

Explore our comprehensive catalog of precision RF connectors and adapters, or contact us today for a custom consultation to ensure your project’s success.

Related Product from Renhotec

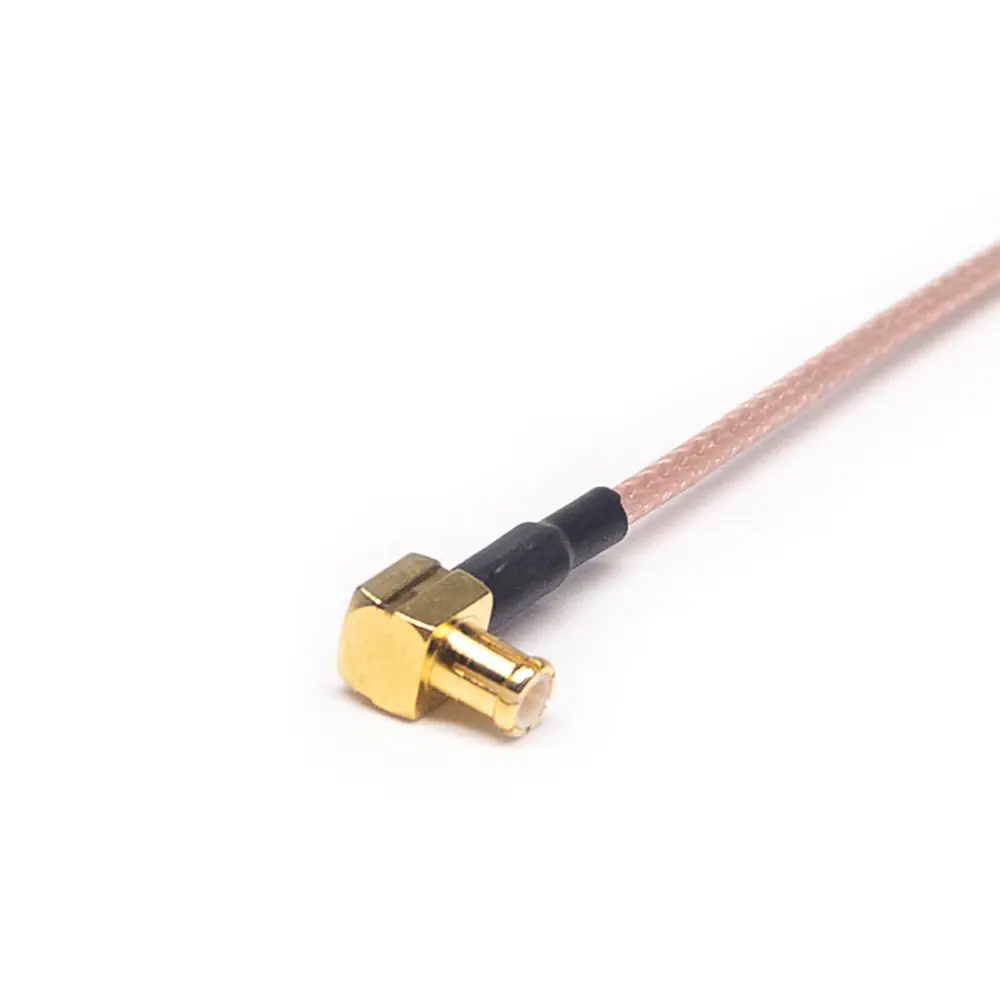

SMA Connectors

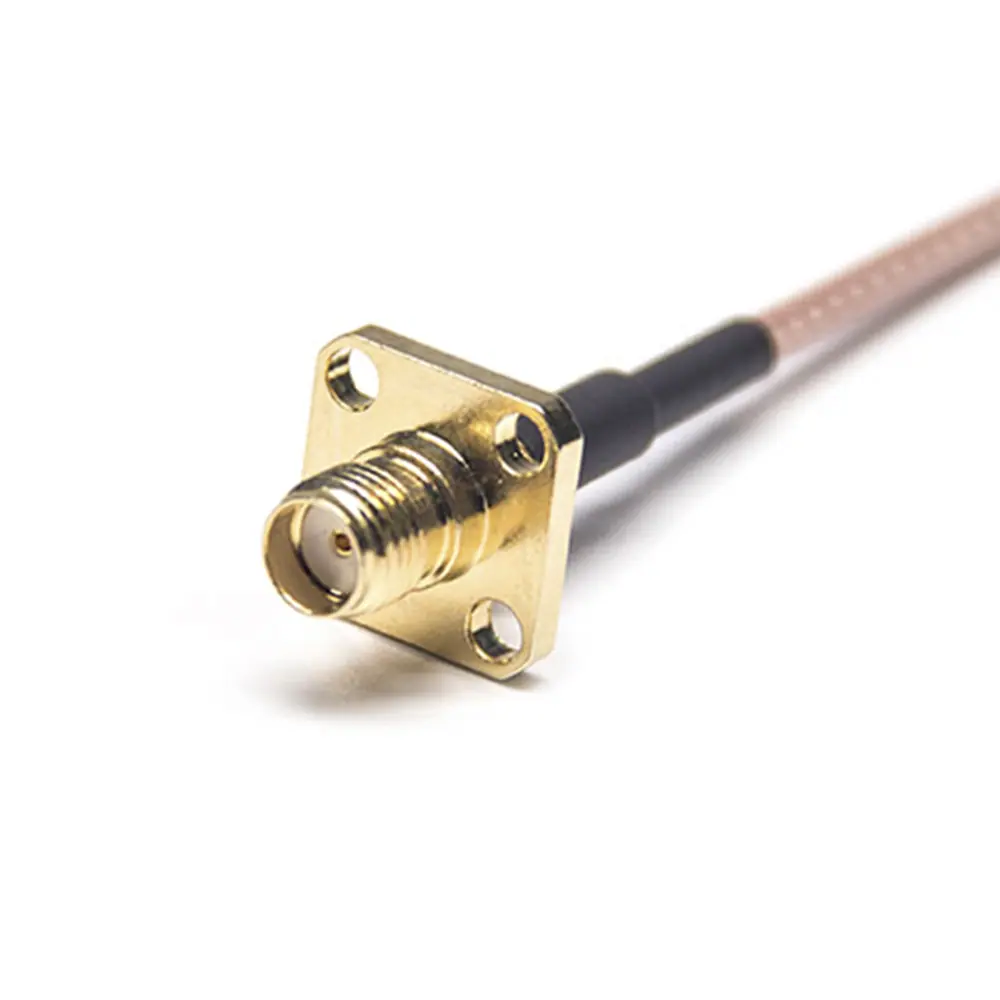

3.5mm Connectors

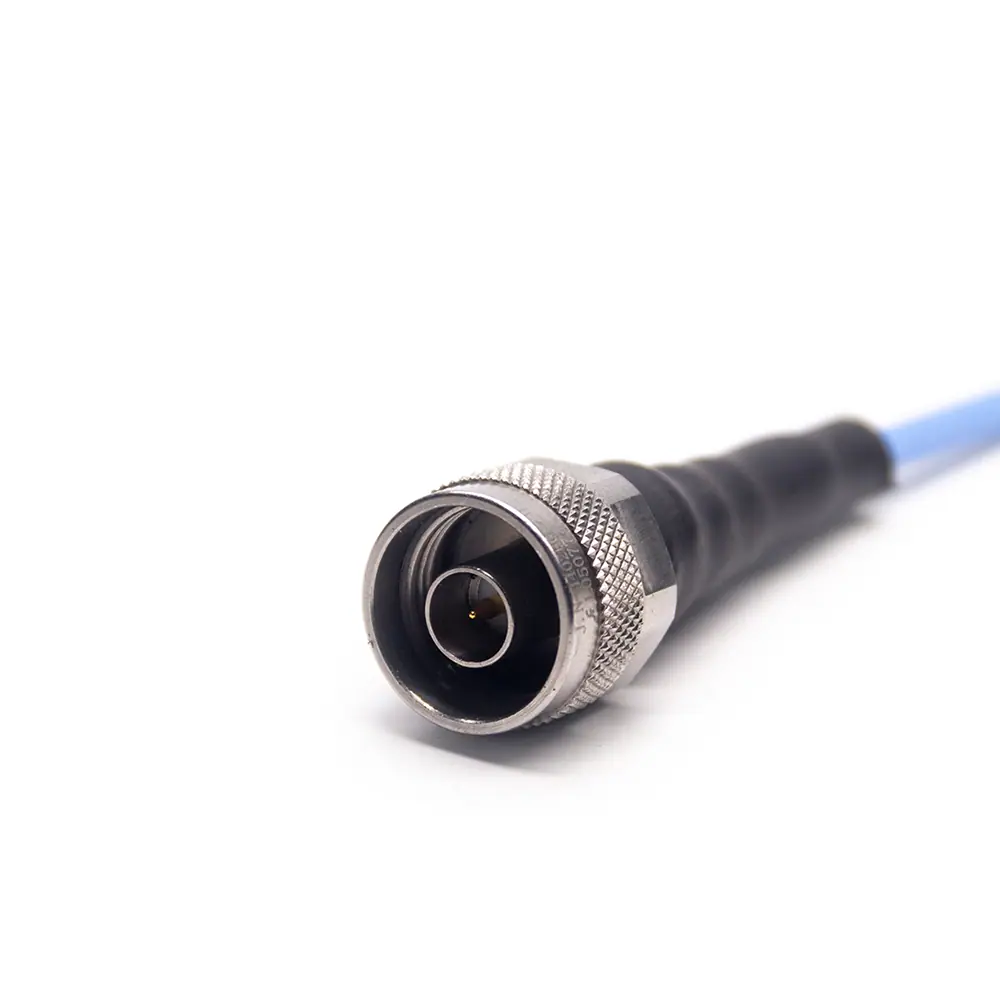

2.92mm Connectors

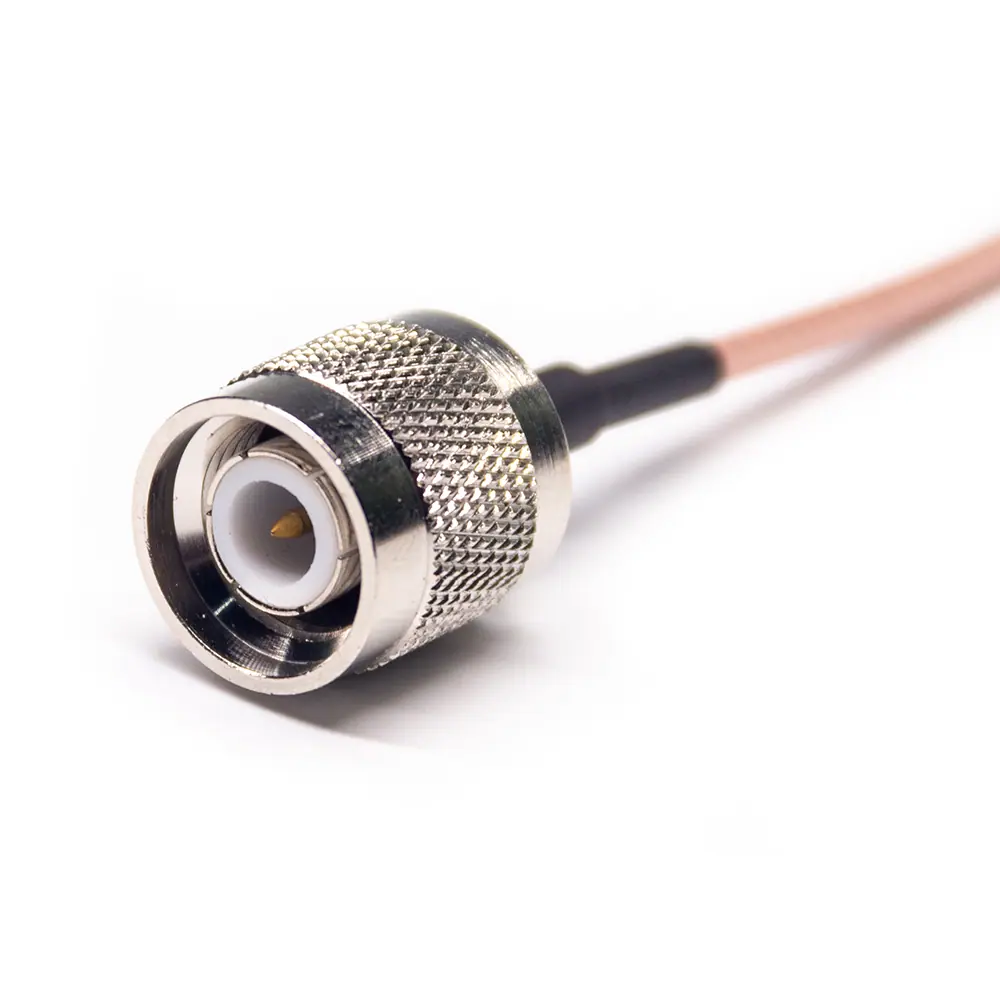

2.4mm Connectors

1.85 Connectors