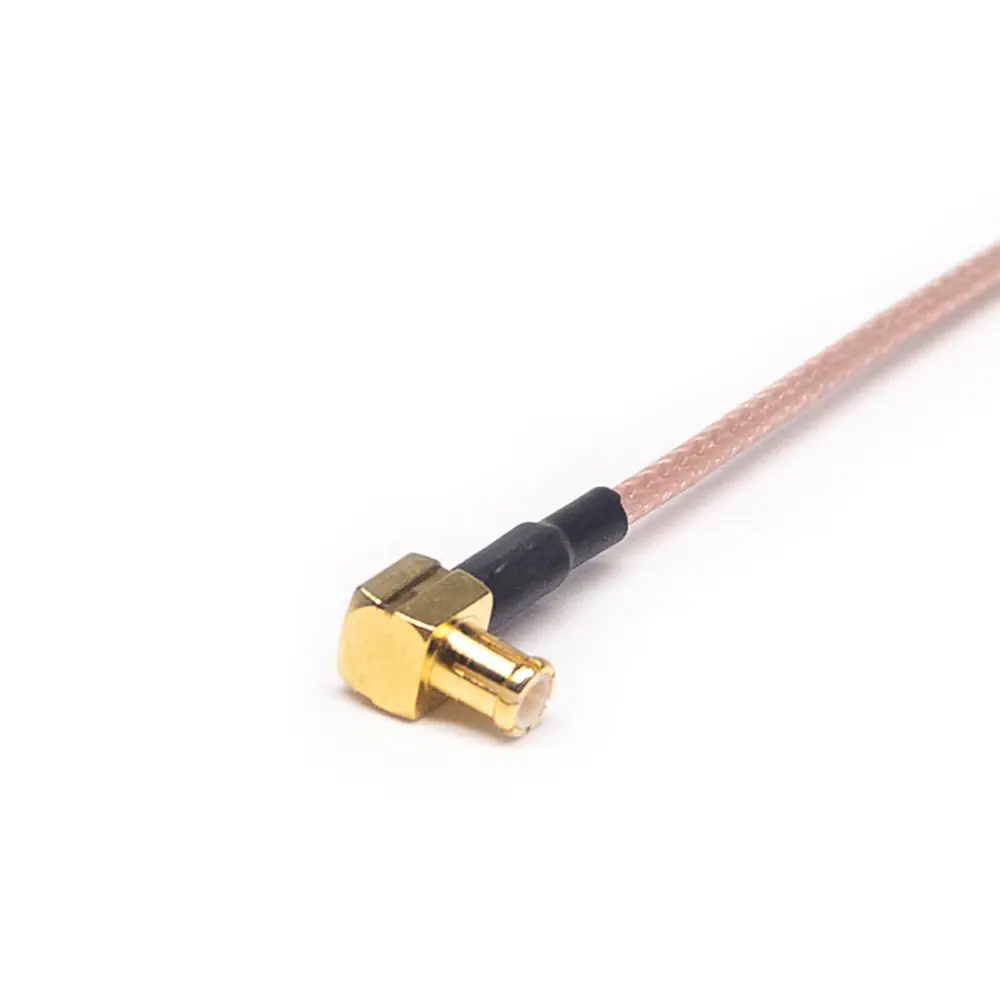

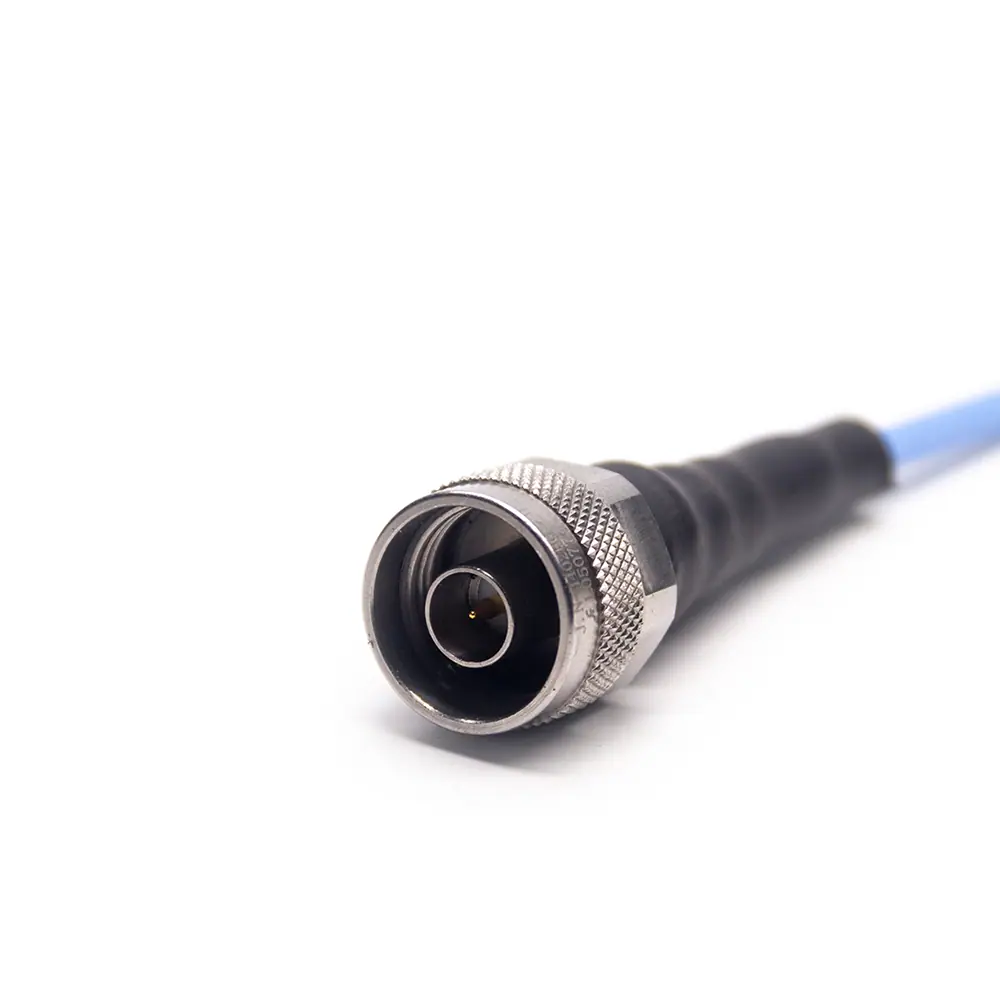

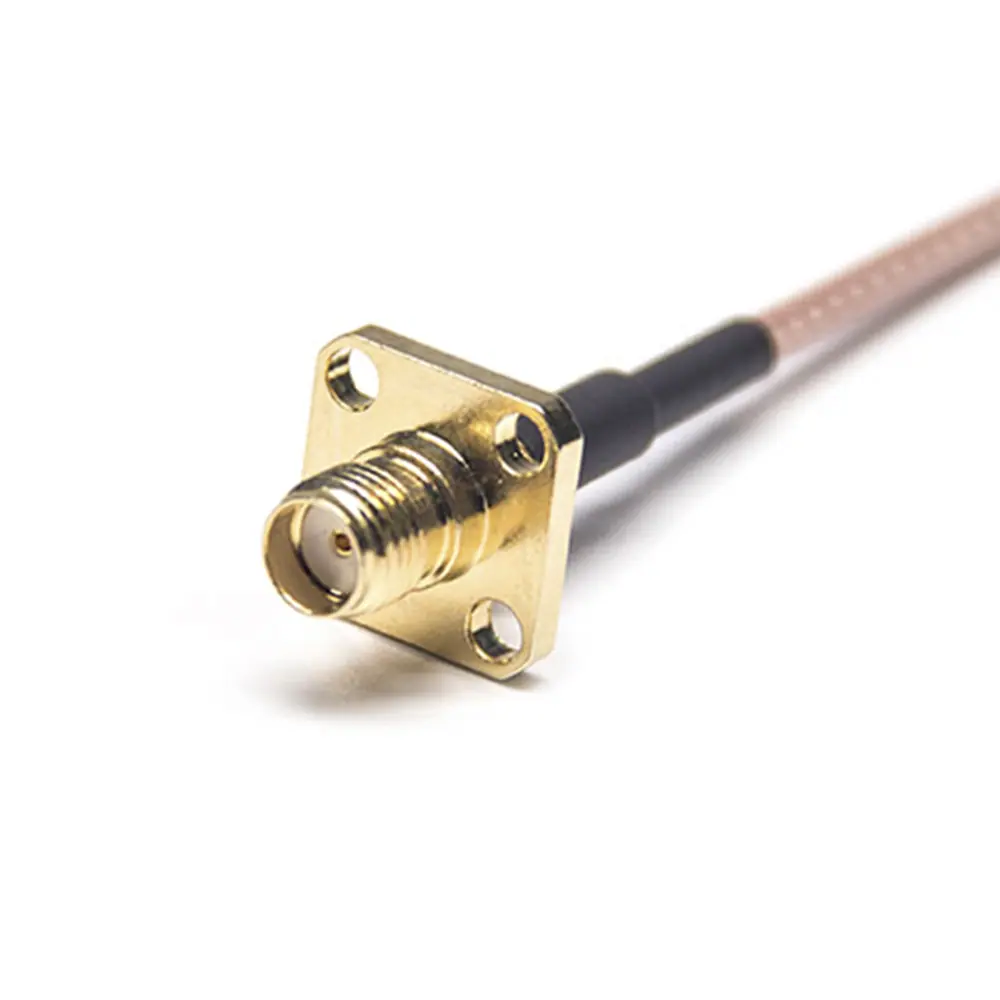

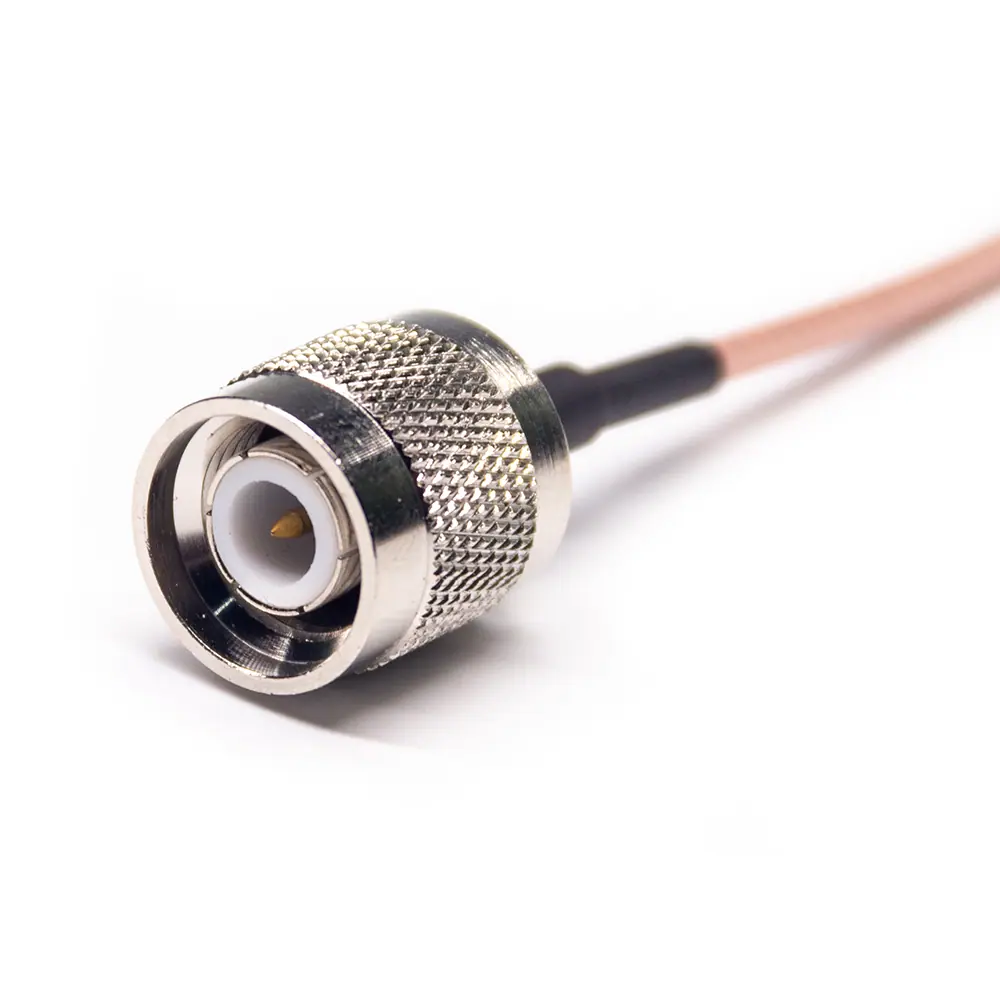

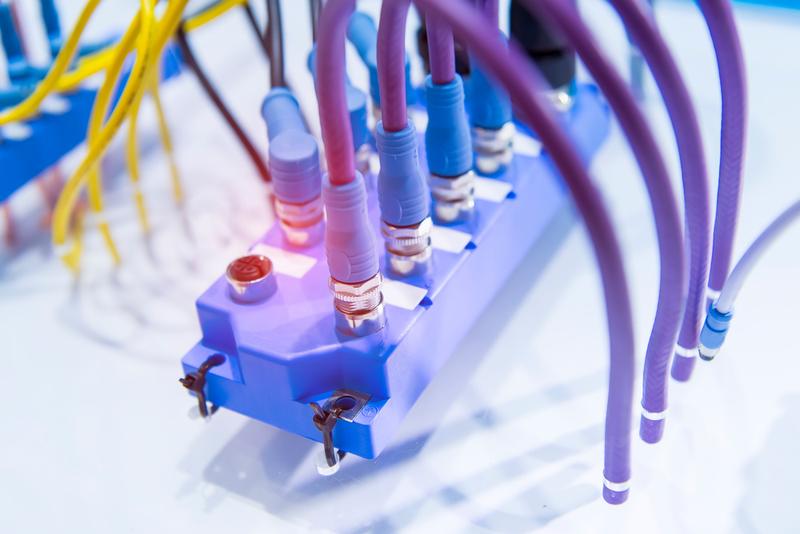

RF Connector & Cable

Introduction to Electronic Connector Insertion and Extraction Force Testing

Electronic connector come in a wide variety of forms and configurations to meet different applications, frequencies, power levels and environmental conditions. The production process typically includes four key stages: stamping, plating, injection molding and assembly. In this article, we will look at the process of testing the insertion and extraction force of electronic connectors.

Objective of the Test

The plug-in force test for electronic connectors serves to establish a standardized method for determining the required insertion force between connectors or the force needed for inserting and removing protective covers and connectors.

Preparations before Testing

During testing, the sample to be evaluated consists of a plug and a corresponding socket, ensuring a matching pair unless stated otherwise. The sample must encompass all applicable components, such as the core, terminal, shell, shield, screws, guides, and any other relevant hardware. It’s crucial to have any auxiliary clips, jigs, or tools prepared in advance for the testing process.

Testing Methodology

The insertion force test involves placing two pluggable electronic connectors in the initial mechanical insertion position, with force and torque gauge readings set to zero. The connector is then gradually inserted at a force rate stipulated by the specifications, and the peak insertion force is recorded. On the other hand, the pullout force test requires fully withdrawing the plug connector at a progressive force rate in line with specifications, and the value of the pullout force is recorded.

Key Considerations

During the test, it’s essential to position the dynamometer dial correctly on the connector to ensure that the reading pointer aligns with the midpoint of the gauge. This alignment guarantees accuracy within ±2%. Lubrication or cleaning methods are unnecessary for the samples unless specified otherwise in the specifications.

About Renhotec Connector Manufacturer

Founded in 2008, Renhe Technology is a connector manufacturer that integrates precision R&D, production, sales and service. The company has a wide range of connector products. Renhe Technology is committed to providing high-quality connector solutions for a variety of applications, serving emerging industries such as inverters, sweepers, charging piles, printers, smart toilets, smart door locks, smart homes, medical electronics and new energy vehicles.

In essence, the process of testing the insertion and extraction force of electronic connector is a critical part of ensuring reliable and efficient connections in various industries. With its extensive experience and commitment to producing first-class connectors, Renhotec has further strengthened its position as a reliable supplier of cutting-edge connector solutions.

This blog is an incredible source of factual and balanced information. I am always impressed with the level of research and depth of analysis that goes into each post.