RF Connector & Cable

The SMA Connector: Exploring Different Mounting Methods

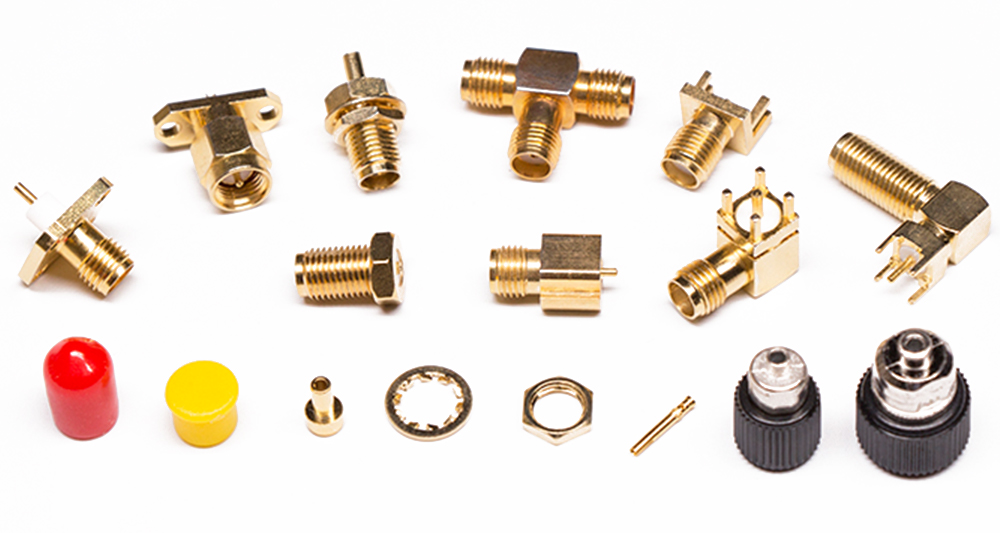

The SMA connector, a widely recognized component in the realm of RF connectors, is prized for its reliability and versatility. It serves as a crucial link between devices in a variety of applications, ranging from telecommunications to aerospace. Understanding the diverse mounting methods available for SMA connectors is essential for optimizing their use within different contexts. Let’s delve into the various mounting options: cable connection, PCB mount, and panel mount.

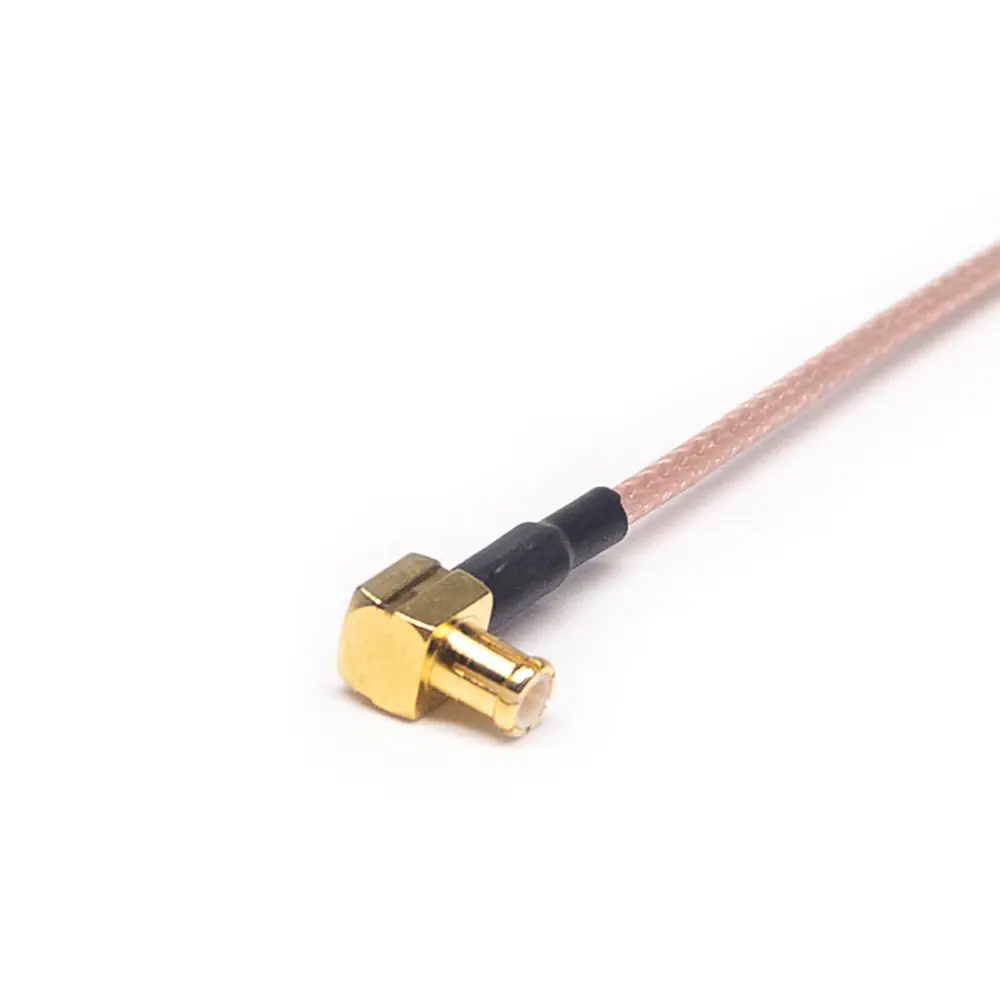

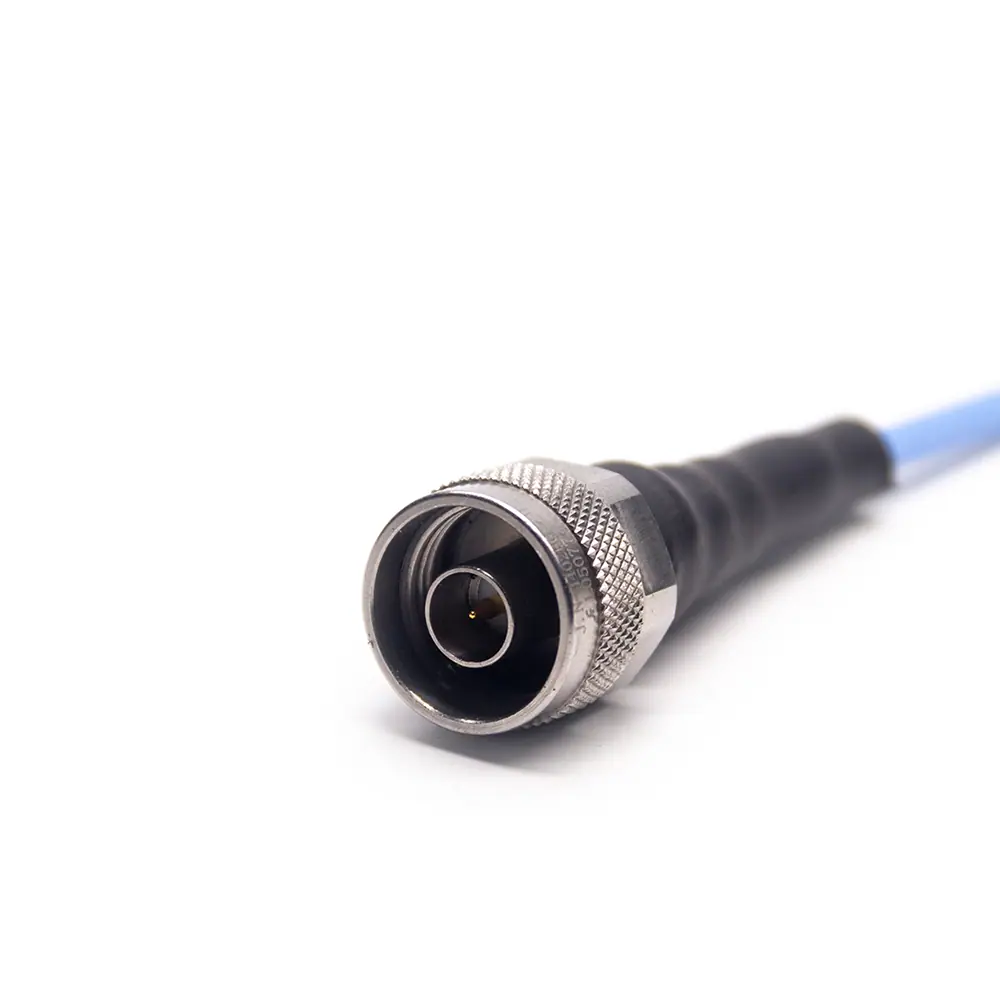

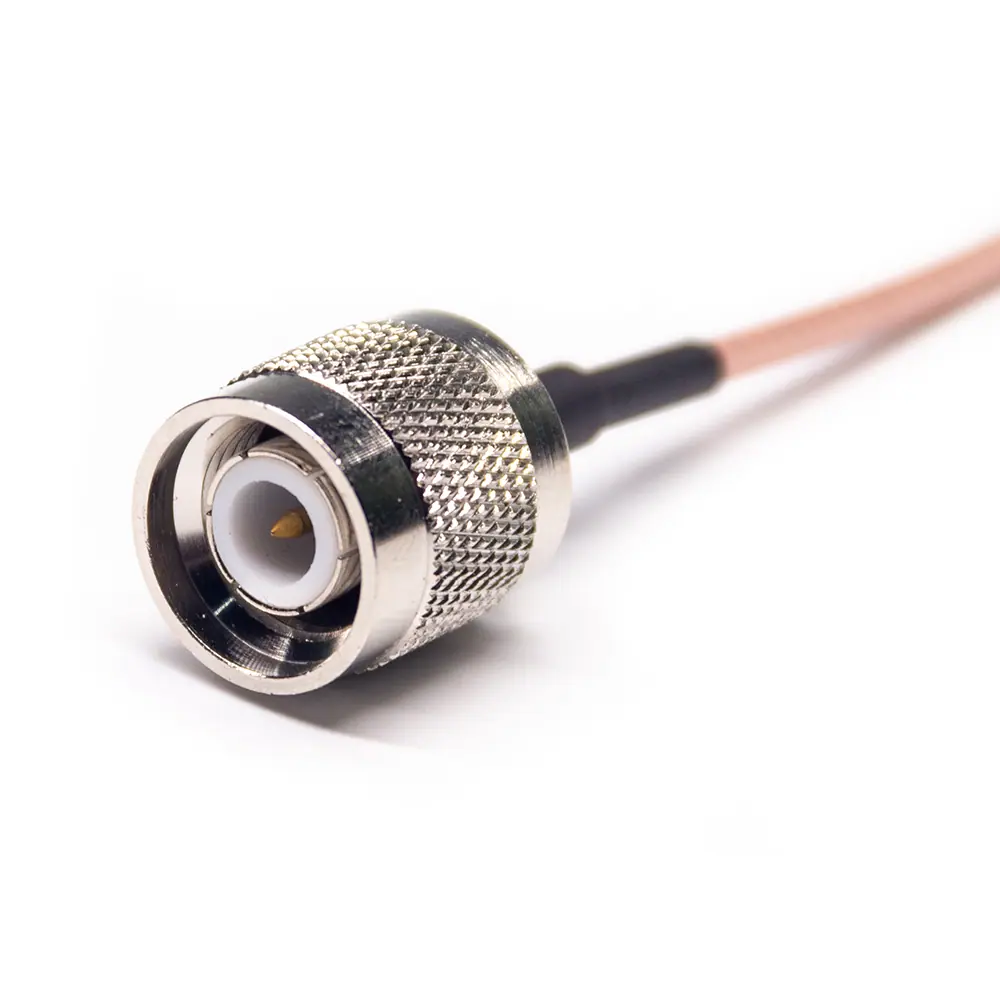

Cable Mount

Connecting SMA connectors to cables can be accomplished through soldering or compression methods. Soldering involves establishing a connection between the connector’s contact and the center conductor of the cable using a soldering process. On the other hand, the compression method involves not only soldering the connector contact to the center conductor but also applying compression to firmly secure the cable within the connector. Compression is particularly efficient, making it a preferred choice for flexible cables. Conversely, soldering is typically employed with semi-flexible cables due to their design and characteristics.

PCB Mount

Integrating SMA connectors into printed circuit boards (PCBs) offers two primary mounting options: through-hole and surface-mount technology (SMT). These connectors are often equipped with gold or tin plating to facilitate the soldering process. Through-hole mounting entails inserting the connector’s leads through holes in the PCB and soldering them on the opposite side, ensuring a robust connection. Alternatively, surface-mount SMA connectors are directly affixed to the PCB’s surface using solder paste and reflow soldering techniques. This approach supports more efficient manufacturing processes and accommodates smaller form factors.

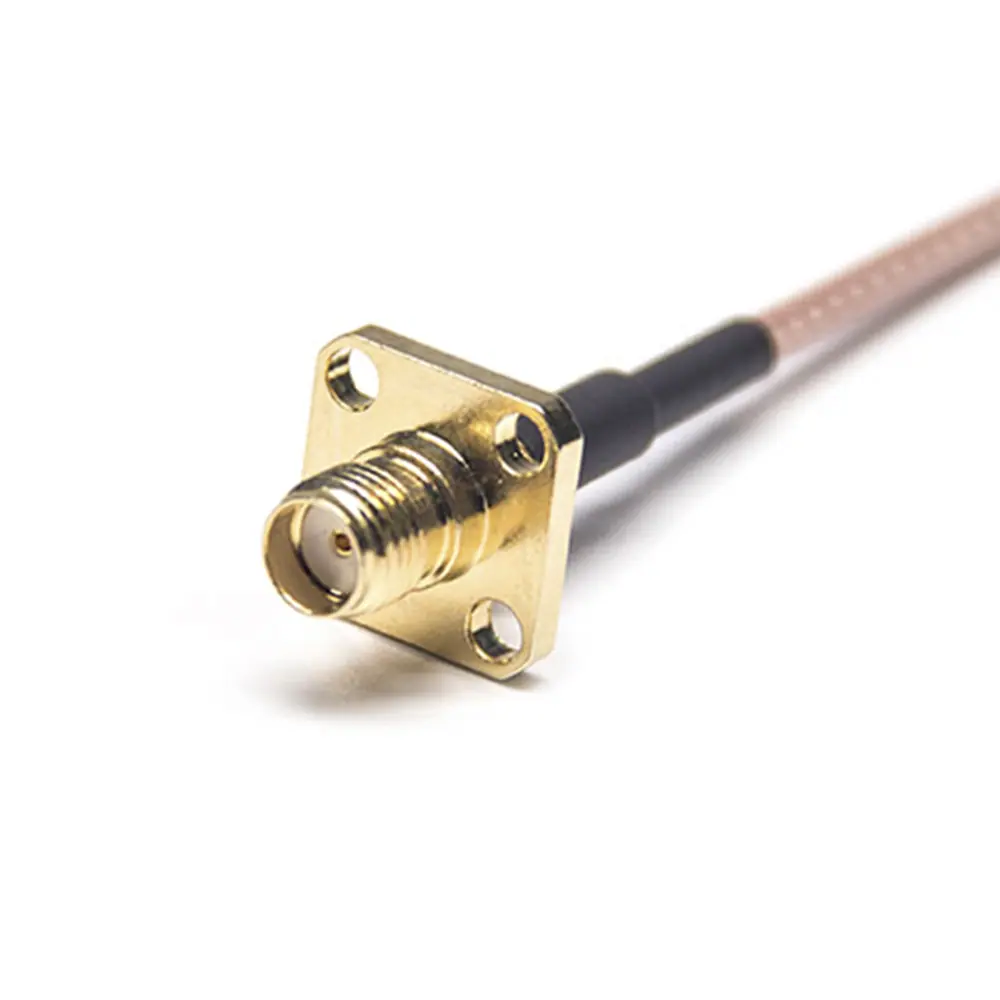

Panel Mount

Panel mount SMA connectors play a pivotal role in bridging external and internal components within devices. They are strategically mounted on panel boxes to facilitate connections that transcend device boundaries. Two common approaches for panel mounting include utilizing a flange mechanism secured with screws and employing threads and nuts to firmly fasten the connector to the panel. These connectors are often designed with waterproofing features, safeguarding the connection against environmental factors.

In Conclusion

Having explored the intricate details of the three primary SMA connector mounting methods—cable connection, PCB mount, and panel mount—it becomes remarkably evident that the versatility of SMA connectors goes beyond just internal configurations. The choice of an appropriate mounting technique empowers engineers and designers to precisely tailor their use of SMA connectors, seamlessly aligning them with the specific requirements of each unique project. This intentional approach ensures not only the achievement of optimal performance but also the establishment of an unswerving foundation of reliability.

Should you require further clarification or have additional inquiries about SMA connectors and their applications, please don’t hesitate to get in touch with us. For a comprehensive overview of our SMA connector offerings, please visit our website: SMA Connector Display. We eagerly anticipate the opportunity to address your connectivity needs and nurture productive collaborations.